Compared with traditional knife cutting, laser cutting adopt non-contact thermal processing, which has the advantages of extremely high energy concentration, small size of spot, less heat diffusion zone, personalized processing, high processing quality, and no “tool” wear. The laser cut edge is smooth, some flexible materials are automatically sealed, and there is no deformation. The processing graphics can be designed and output by the computer at will, without the need for complicated die tools design and production.

In addition to improving efficiency, saving materials, creating new processes, improving product quality, and giving products higher added value to laser flexible processing, the cost performance of the laser machine itself is much higher than that of traditional cutting tool machines.

Taking the flexible materials and solid materials fields as examples, the comparative advantages of laser cutting machines and traditional tools are as follows:

| Projects | Traditional knife cutting | Laser cutting |

| Processing methods | Knife cutting, contact type | Laser thermal processing, non-contact |

| Tool type | Various traditional knives and die | Lasers of various wavelengths |

1. Flexible materials segment

| Traditional knife cutting | Laser processing | |

| Tool wear | Need to configure tool module, easy to wear | Laser processing without tools |

| Processing graphics | Restricted. Small holes, small corner graphics cannot be processed | No restrictions on graphics, any graphics can be processed |

| Processing materials | Restricted. Some materials are easy to fluff if processed with knife cutting | No restrictions |

| Engraving effect | Due to contact processing, it is impossible to engrave fabric | Can fast engrave any graphics on the material |

| Flexible and easy operation | Need to program and make knife mold, complicated operation | One-key processing, simple operation |

| Automatic edges sealed | NO | YES |

| Processing effect | There is a certain deformation | No deformation |

Laser cutting machines and laser marking machines occupy a major market share in small and medium power laser processing equipment, and are the most widely used processing systems in small and medium power laser processing.

The core component laser generator of medium and small power laser machines mainly uses CO2 gas tube laser. CO2 gas lasers are classified into DC-excited sealed-off CO2 lasers (hereinafter referred to as “glass tube lasers”) and RF-excited sealed-off diffusion-cooled CO2 lasers (the laser sealing method is a metal cavity, hereinafter referred to as “metal tube lasers” ). The global metal tube laser manufacturers are mainly Coherent, Rofin and Synrad. Due to the mature technology of metal tube lasers in the world, they are widely used. With the industrialized production of metal tube lasers, the global market for small and medium power metal tube cutting and processing equipment will show a rapid growth trend.

In foreign laser companies, it is the mainstream direction to equip small and medium-power laser machines with metal tube lasers, because stable and reliable product quality, higher efficiency and more powerful functions have made up for their high price. High cost performance and good after-sales service will promote the development of small and medium-power laser processing equipment industry and increase the proportion of laser cutting machines industry applications. In the future, the metal tube will enter a mature stage and form a scale effect, and the market share of metal tube laser cutting and processing system will maintain a steady upward trend.

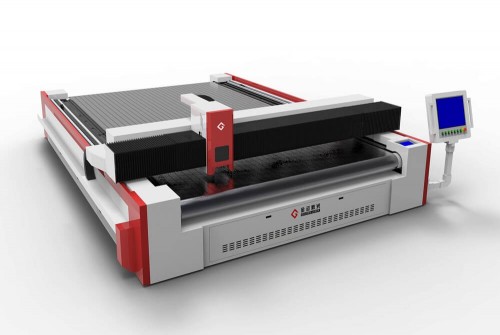

In the field of small and medium power laser cutting, Golden Laser is a well-known manufacturer in China. Under the influence of the COVID-19 pandemic, its market share is still showing a clear upward trend. In 2020, the sales revenue of Golden Laser in the small and medium power laser equipment segment increased by 25% compared with the same period in 2019. This is mainly due to the company’s marketing strategy of focusing on developing potential markets, cultivating subdivided industries, providing customers with customized laser mechanics solutions, and customer-centric R&D and promotion of new products.

Golden Laser‘s small and medium power laser equipment product line involves industrial fabrics, digital printing, garments, leather and shoes, packaging and printing, advertising, home textiles, furniture and many other applications. Especially in the field of textile fabric laser application, Golden Laser was the first to be involved in China. After more than ten years of precipitation, it has established an absolute dominant position as the leading brand in textile and apparel laser applications. Golden Laser can independently research and develop motion control systems, and the industry software used in its models are independent research and development, and its software development capabilities are in a leading position in the industry.

There are numerous downstream applications of small and medium power laser cutting machines. The industrial textile industry is one of the downstream segments of CO2 laser cutting machines. Taking automotive textiles as an example, in recent years, China’s non-woven fabrics have been used in the automotive industry in the amount of nearly 70 million square meters each year. The automobile manufacturing industry is booming, and the demand for non-woven fabrics and other industrial fabrics is also increasing, and this data only accounts for 20% of the demand for non-woven materials.

Behind the rapid development of the automotive industry is the rapid increase in the amount of automotive decorative fabrics. This means car roof interior fabrics, door panel interior fabrics, seat covers, airbags, seat belts, roof non-woven fabrics, backings, seat cover non-woven fabric linings, tire cord fabrics, fiber-reinforced polyurethane foam boards, car mat carpets, etc. are in large demand and grow rapidly. And this undoubtedly provides huge business opportunities for automobile supporting enterprises, and also brings good development opportunities for upstream cutting equipment enterprises.

Post time: Feb-24-2021