As an indispensable means of transportation in modern life, automobiles are expanding more and more related industries with the improvement of living standards, such as car seats (ventilated seats, heated seats), car seat covers, cushions, feet pad, and so on.

Market analysis of the automotive interior industry

According to data analysis, the market size of car seat covers shows a continuous growth trend and is predicted to grow at a compound annual growth rate of 4.0% in the next 10 years. To a large extent, this stems from the continuous research and update of automotive textile materials and consumers’ fashion pursuit of automotive interiors, both of which have greatly promoted the development of automotive seat covers. And the seat cover has the prominent function of protecting the car seat and decorating the internal environment of the car and is loved by car owners and passengers, which further promotes the growth of the car seat cover market. Moreover, the tax reduction policies adopted by some governments for automobile manufacturers have also injected vitality into the development of automobile derivative industries. Not only the car seat cover industry, but also related industries such as car heated seats, ventilated seats, and car mats also benefit from it.

From the perspective of vehicle models, passenger cars are developing at a faster rate and maintaining high-profit growth during the forecast period, which provides a broader development space for the automotive seat cover industry. On the other hand, consumers’ requirements for comfort and safety have prompted auto interior manufacturers to continue to innovate. For example, car seat covers are enriched and diversified with various textures and design patterns. Car seat by adding ventilation and heating elements can provide passengers with comfortable riding experience, whether in summer or winter.

Innovation in processing technology

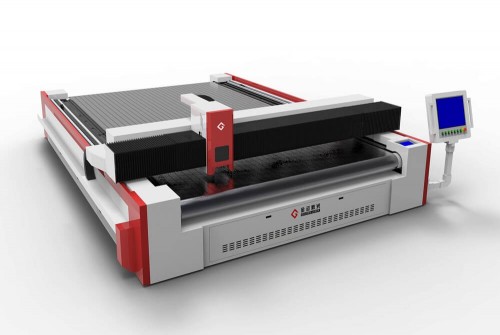

In addition to design innovations, the processing technology has also changed because the traditional processing technology no longer meets the processing of complex designs and varieties of materials. As far as car seat covers are concerned, different materials can provide different comfort experience for consumers. Seat covers made of nylon, mesh, vinyl, and other materials can all be processed by laser cutting technology. And with high cutting precision and edge sealing in time, laser cutting can achieve perfect seat covers with clean edges.

For car seats, whether it is a ventilated seat or a heated seat, laser cutting and laser perforating technologies have been widely used. The ventilated seat utilizes the holes in the car seat to transmit the airflow from the inside of the seat to the surface of the seat so that the air in the hips and back can circulate. How to achieve precise and dense perforation in the car seat? Laser cutting and laser perforating have the advantages of high precision and high efficiency, which precisely meets this production demand, solves problems for car seat manufacturers, and improves market competitiveness. Furthermore, laser cutting technology is also widely applied to the cutting of components of heated seats, especially non-woven fabrics attached with copper wires (an important heating element of heated seats) which can be contour recognized to complete precise cutting by laser cutting machine equipped with automatic visual recognition system.

Automotive interior accessories are constantly enriching our travel experience, and laser technology continues to innovate and develop to provide automotive interior upholstery manufacturers with more efficient and high-quality processing solutions. Goldenlaser with over 20 years experience is not only committed to producing laser equipment that meets market needs but also creates customized laser solutions according to the specific needs of each customer, making full use of the advantages of laser cutting, laser engraving, laser perforating and laser marking to solve actual production problem for customers.

We are always looking forward to hearing from you if you are looking for laser processing solutions or have any insights on laser technology!

Post time: Sep-19-2020