For the apparel industry, people are more inclined to customize apparel. The emergence of digital printing machines just meets this demand.

The introduction of inkjet technologies injects new vitality into the fashion and apparel industry. From the first machine Stork Fashion Jet in the mid-1990s to the 2018 EFI Reggiani BOLT single-pass printer, the digital speed of the digital printer reached 90 meters per minute. The World Textile Information Network data shows that the output of the digitally printed fabrics has reached 2.57 billion square meters, of which 85.6% are used in the garment, fashion, and textile industries.

Many brands have also begun to use this technology to update their industrial structure: Zara is using the technology to produce collections throughout the year. Nike launched the ‘Nike By You’ scheme, allowing consumers to create their custom shoes. Amazon’s fully automated, on-demand manufacturing line also combined with the use of digital printers.

The advantages of digital printing technology in the apparel industry

1. Samples can be modified and tested at the printing site to reduce the turnaround time

2. Personalized customization shortens the cycle from order to production to sale

3. The consumer will wear digitally printed clothing for a longer period and are more dependent because of customized and personalized production,

4. Digital printing technology is more environmentally friendly and reduces textile waste

5. On-demand production and small batch and multi-variety production solves the problem of inventory backlog

6. That high-resolution pattern and image prints make the style of clothing more diverse

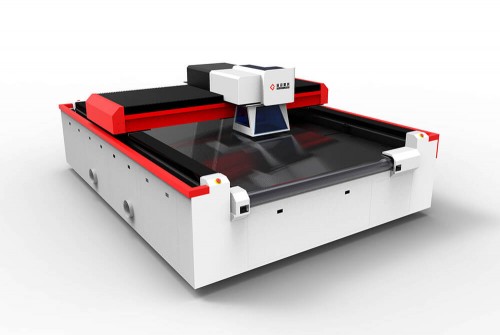

7. The combined use of digital printing technology and laser system improves production efficiency and reduces costs

The future directions of digital printing technology in the apparel industry

1. Metallic or glitter inks technology has not been broken through yet

2. How to connect the supply chain in the Fourth Industrial Revolution and what technological breakthroughs need to be made to achieve the sustainable development of digital printing

3. How to combine digital printing technology with upstream and downstream industries to simplify the production process. For example, the use of laser cutting equipment to cut digital printing can greatly shorten the production cycle of clothing and improve production efficiency

More importantly, laser cutting is the most suitable processing method for the cutting of digitally printed patterns. First of all, digital printing technology and laser cutting technology have a lot in common, both of which can provide customized clothing services, and have the characteristics of on-demand production. Secondly, the two technologies complement each other. Digital printing equipment can provide a variety of patterns for laser cutting clothing. Laser cutting machine also ensures high precision and high efficiency for pattern cutting, saving labor, and processing time to reduce costs. Besides, the integrated processing from digital printing patterns to laser cutting patterns to pattern sewing simplifies the production process and greatly shortens the production cycle. (Additional: clothing can be cut and perforated by CO2 laser machine. Therefore, it is an excellent choice to use digital printing equipment in combination with laser equipment)

Post time: Apr-28-2020