Cordura is a collection of fabric technologies that are durable and resistant to abrasion, tearing and scratching. Its use has been extended for more than 70 years. Originally created by DuPont, its first uses were for the military. As a kind of premium textiles, Cordura is widely used in luggage, backpacks, trousers, military wear and performance apparel.

In addition, relevant companies have been researching new Cordura fabrics that combine functionality, comfort, blending a variety of rayons and natural fibers into Cordura to explore and study more possibilities. From outdoor adventures to daily life to the selection of workwear, Cordura fabrics have different weights, different densities, blends of different fibers, and different coatings to achieve multiple functions and uses. Of course, to get to the root of it, anti-wear, tear-resistant, and high toughness are still the most essential characteristics of Cordura.

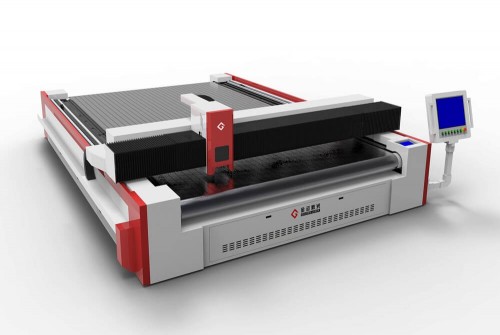

GoldenLaser, as an industry-leading laser cutting machine manufacturer with 20 years of experience, has been dedicated to the research of laser applications in a wide array of technical textiles and industrial fabrics. And also very interested in the currently popular functional fabric – Cordura. This article will briefly introduce the source background and market status of Cordura fabrics, hoping to help individuals and manufacturers understand Cordura fabrics, and jointly promote the development of functional textiles.

Source and Background of Cordura

Originally born during World War II, “Cordura durable cord rayon tire yarn” was developed and named by DuPont and implanted into the tires of military cars, greatly improving the wear resistance and durability of the tires. So Cordura often said now is speculated to be derived from the two words cord and durable.

This kind of fabric is popular and valued among military equipment. During this period, ballistic nylon was developed and widely used in protective equipment such as bulletproof vests and bulletproof jackets to protect the safety of soldiers. In 1966, due to the emergence of nylon with more superior performance, DuPont began to blend nylon into the original Cordura in different proportions to develop the Cordura® we are now familiar with. Until 1977, with the discovering of Cordura dyeing technology, Cordura®, which has been working in the military field, began to move into the civilian field. Opening the door to the new world, Cordura, quickly occupied the market in the luggage and other apparel sectors. It is reported that it had occupied 40% of the soft luggage market at the end of 1979.

Premium resistance to tears, abrasion and punctures has always made Cordura a first-class position in industry applications. Combined with good color retention and developing new blending with other fabrics technology, Cordura are obtaining more special functions of water repellence, authentic look, breathability, and lightweight.

How to Achieve Cordura Textiles with Good Performance

For many manufacturers and individuals in outdoor equipment and fashion fields, figuring out the performance and properties of versatile Cordura fabrics and choosing suitable processing solutions for different Cordura fabrics goods from various industries can help to understand the market condition and seize developing opportunities. Laser cutting technology is recommended firstly, not only because laser processing has excellent and unique advantages for cutting and engraving fabrics and other non-mental and mental materials, like heat treatment (sealing edges during processing), contactless processing (avoiding materials deformation), and high-efficiency and high quality, but also because we have made tests for laser cutting Cordura fabrics to achieve good cutting effects without destroying fabrics itself properties.

Hoping this article can convey helpful information for you. Regarding the characteristics of Cordura materials and laser cutting Cordura fabrics and other functional clothing, we will continue to share our latest research with you. For more information, welcome to enter GoldenLaser’s official website for inquiries.

Email [email protected]

Post time: Mar-23-2021