Textiles have continuous vitality in the fiercely competitive and evolving market. For one this is due to the long product life cycle of textiles, which has driven the development of a series of related industries, from the raw material collection, processing, printing, cutting and stitching, sales to use by consumers can be said to be a basic life cycle of textiles (if recycling and other processes are added, the life cycle is bound to be longer). Another important reason is that the public’s demand for textile products is huge and will continue to grow despite the current epidemic situation.

As far as the digital textile printing market is concerned, the broad market prospects and potential development space have attracted textile manufacturers in many fields to embrace digital printing technology, including clothing, home textiles, advertising, and industrial fabrics. The scale of the digital textile printing market is predicted to reach 266.38 billion US dollars in three years. It will occupy a huge market share coupled with the support of digital printing technology and the increase in consumer demand. Compared with traditional textile printing technology, digital textile printing has more prominent advantages that is suitable for market demand, which will make it gradually replace traditional textile printing in market competition.

Why digital printing textile can be an alternative to traditional printing

Efficient production

Driven by the market, digital printing textile technology has shown strong development in recent years. The ever increasing demand for digital printing printers has prompted printer manufacturers to start looking for higher-speed and large-capacity printing systems. The printing speed has jumped from 10 meters per hour 15 years ago to the current 90 meters per minute. This is the result of the collaboration between software engineers, equipment engineers, and chemical researchers in many aspects. More importantly, the rapid increase in ink printing speed means that digital printing has achieved leapfrog development and provides favorable support for its replacement of traditional printing.

The advantages of digital printing are far more than this, the continuous evolution and development of ink technology are embodied in the expansion of the dye color gamut and the colorful presentation of multiple color effects, which are largely related to the individual needs of consumers.

Water-saving and energy saving

According to statistics from the traditional printing market, printing in the fashion industry in the next 10 years is estimated to consume 158 billion cubic liters of water each year. This is a large amount of water consumption in those water-scarce regions of the world, where precisely a large number of industrial printing products are produced. Therefore, reducing water consumption and alleviating environmental pressure has made digital textile printing a clear advantage in the competition with the traditional printing industry. Not only save a lot of water for processing and printing, but digital textile printing also has lower chemical consumption and carbon emissions. Catering to the world’s environmental protection and sustainability concepts, digital printing can reduce carbon emissions by nearly 80% with the support of technology. While saving energy, it also reduces certain production costs, which undoubtedly makes digital printing the focus of textile printing manufacturers.

Challenges and solutions facing the digital textile printing industry

Challenges and opportunities coexist. The digital textile printing industry is facing considerable supply chain pressure. Under the influence of the epidemic, seeking digitization of the supply chain may help printing companies tide over the difficulties. As far as the dye-sublimation printing market is concerned, diversified product mix and processing are more conducive to the development of the dispersed market. The great results can be achieved through multi-faceted cooperation in multiple industries.

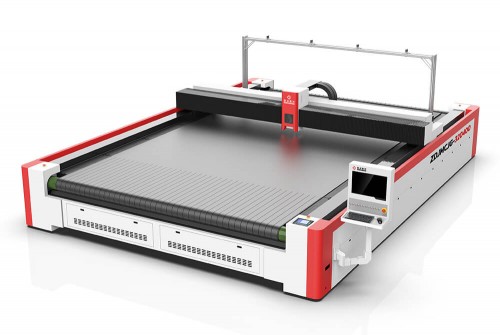

The combination of laser cutting technology and digital textile printing technology can push the printed textile market to faster development speed. The continuous development of laser cutting technology assists the processing of digital printing textile products with its unique advantages.

1. Heat treatment can make the edge of the fabric material be fused during processing, eliminating the need for subsequent processing.

2. The high precision of laser cutting can achieve high-quality fine cutting effects.

3. The adoption of CNC system can achieve high automation, saving labor costs and time costs.

4. A variety of printed patterns in fabrics can be recognized by the laser system and then accurately cut to meet the individual needs of consumers.

Goldenlaser has been committed to the research of laser technology and the production of laser equipment for more than 20 years. We hope that laser cutting technology can help you realize the processing of digital textile printing products with high efficiency and high quality. If you want to know more laser-related information, please contact us!

Post time: Sep-07-2020