Austrian leather and upholstery specialist, Boxmark, regularly cooperates with aircraft interior designers on projects, which creates insights to enable the company to anticipate upcoming seat design trends. One of the trends currently identified – perhaps unsurprisingly – is that passengers want to enjoy the comfort and convenience of their home while flying.

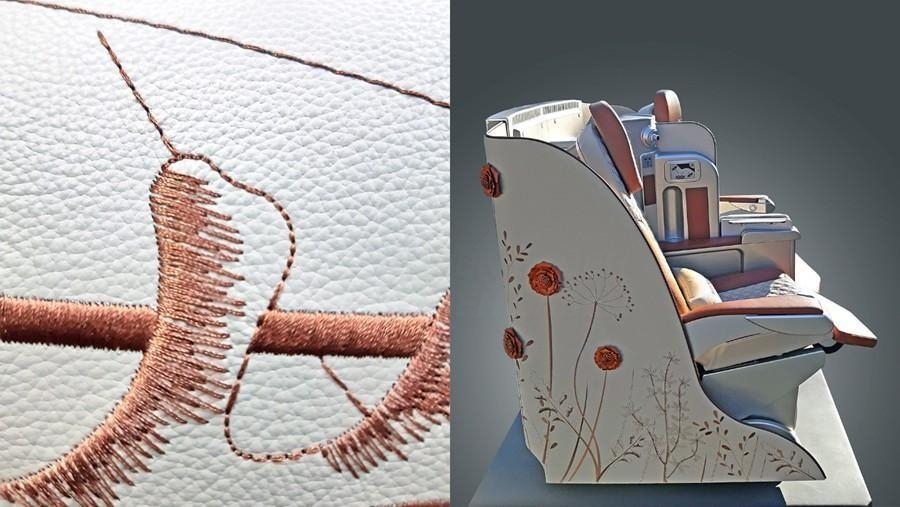

Passengers’ higher demand for personalization and comfort promotes the innovative development of aircraft seats. “With the business class bench, we are adding various design elements, including quilting and hand-crafted embroidery, to show how to meet the trend towards greater comfort but also individualization,” says Gollner. says Rupert Gollner, head of the air division at Boxmark.

Also, combined with the design of heated car seats, aircraft seat manufacturers are constantly innovating in seat materials to meet the requirements of safety, comfort, and durability.

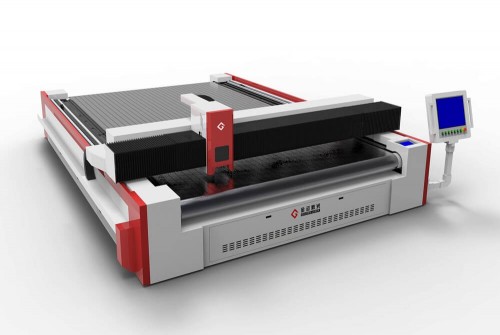

In short, with the consumer’s requirements for personalization and comfort and the development of technology, aircraft seats are also constantly innovating. Faced with such a broad market prospect, aircraft seat manufacturers must need suitable processing solutions to help them achieve these goals.

The laser processing technology is advancing with the times. While improving the processing quality, reducing labor costs and time costs, it also meets the modern people’s personalized needs. Moreover, laser processing technology has gradually matured and is widely used in automotive, aviation, electrical appliances, and other fields. The laser system will definitely bring you perfect processing works and considerable benefits.

Post time: Aug-31-2020