Facial masks are actually processed by laser?

Shocked!

But why can laser do this?

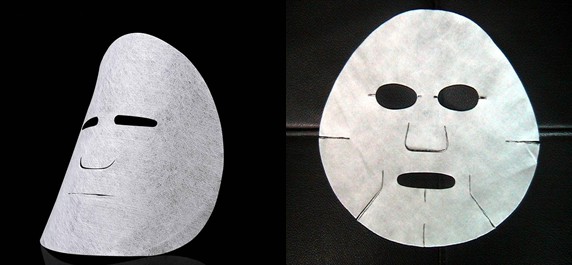

When it comes to lasers, most people are used to cut industrial fabrics. But what everyone did not expect is that the laser is actually so close to our lives. The facial masks that people usually use are also processed by advanced laser technology.

In facial masks production, knife cutting is a common and traditional processing method. Although the processing efficiency is very fast, after the multi-layer cutting, the facial masks may have a certain deformation, because the masks on the market are usually made of silk and non-woven fabric. The slight deformation may cause the low degree of fit of the mask, which leads to the extent of absorbing and absorbing the essence and cause skin problems. So why can laser solve this problem perfectly, thanks to the advantages of laser processing:

1. Precise cutting

Laser is non-contact cutting, and the cutting error can be controlled within 0.1m. It is very accurate to keep the facial masks produced at the design size without any deformation.

2. Clean cutting edges

Laser cutting laser is thermal processing and has the ability to automatically seal edges, which ensures smooth edges and avoids scratching the user’s skin.

Is there a new understanding of laser? Goldenlaser not only focuses on the cutting of industrial fabric products but also focuses on bringing laser technology to people’s lives, such as non-woven fabric(Polyester, polyamide, PTFE, polypropylene, carbon fiber, glass fiber, and more)processing. Check out our non-woven laser cutter!

Post time: Feb-11-2020