Ventilation ducts connect indoor air with outdoor air. Indoor personnel can enjoy the comfortable experience of different temperatures controlled by the system, whether in summer or winter. Air circulation can not only reduce the risk of disease transmission but also benefit physical and mental health. Therefore, enterprises and factories usually use air dispersion to optimize the indoor environment, which further improves the efficiency of employees.

With the market’s preference for light materials and the increasing emphasis on environmental protection, the fabric ducts came into being. According to market data analysis, the compound annual growth rate of the air ducts is predicted to exceed 3% in the next five years. This shows that the market for fabric ducts is developing rapidly and has great potential. The fabric ducts mostly made of polyester fiber and glass fiber have the characteristics of lightweight, which is in line with the current and future development trend of light buildings to reduce the burden of building. And the waste plastic can be recycled into the raw material of the fabric ducts, which achieves the sustainable development of the cycle and conforms to the current environmental protection concept.

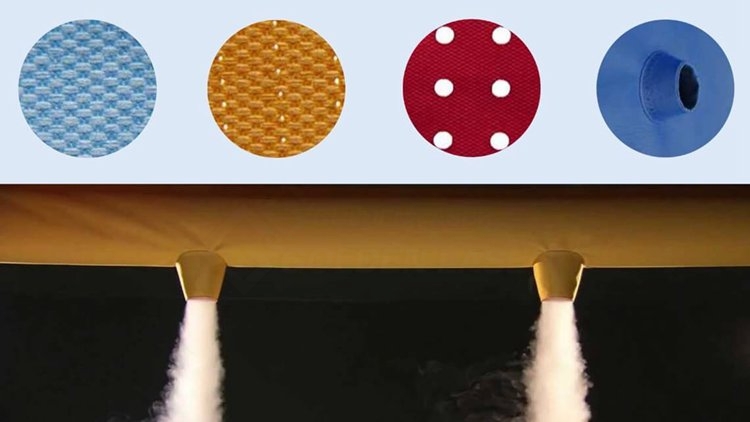

Besides, customized services have brought new opportunities and vitality to the fabric ducts industry. On the one hand, the multiple selectable colors of the textile ducts can adjust the employee’s mood in different working environments compared to the single tone of the metal ventilation ducts. And patterns and logos can be customized and printed on the fabric ducts, which also reflects the company’s philosophy and characteristics and has a positive impact on employees’ emotions.

On the other hand, different sizes and different shapes of holes on the fabric ducts can also be customized to provide a more comfortable experience according to the spatial characteristics. The fabric ducting and diffusers can control the air volume and direction by using breathable fabric, micro holes, small holes, nozzles so that fresh and clean air is distributed to all corners of the space without “dead zones”.

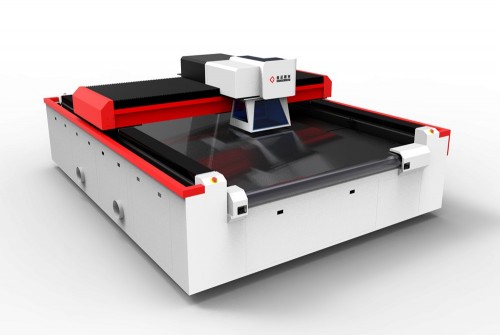

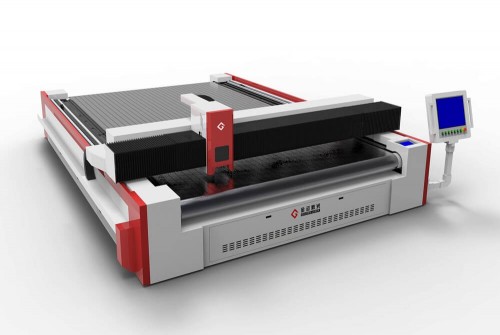

The fabric ductwork has such superior performance, and then you must be interested in the processing of the fabric ducting, especially Perforating. The laser system can perfectly solve the perforating problem of the fabric ducts. Due to the high precision and thermal processing technology, the laser system can cut a variety of holes and nozzles with clean and smooth edges according to the different needs of manufacturers to provide the most suitable service. We are happy to be able to help you if you want to learn more about laser systems and the fabric ducts processing.

Post time: Jul-13-2020