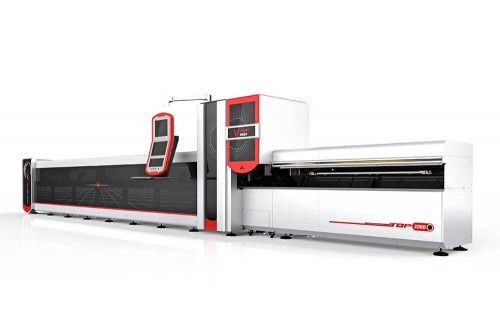

Features of the Fiber Laser Cutting Machine

Fully enclosed design

Fully enclosed structure design completely isolates all visible lasers inside the unit, reducing the risk of laser radiation and providing safer protection for your processing environment.

The dust fumes generated by laser cutting of metal are all isolated inside the fully enclosed structure. According to the dynamic flow law of dust smoke, the top multi-distributed suction design is combined with the large suction fan to minimize the dust pollution during the processing of fiber laser cutting machine, to keep the working environment clean and to protect the health of the operators.

Control Console

Abandoning the traditional integrated operation console on the equipment casing, the external rotary control console is utilized to preserve the integrity of the overall appearance of the fiber laser cutting machine, and is in line with the industrial design standards of high-end CNC machines.

The console is 270 degrees wide-angle three-dimensional space rotation, supporting multi-dimensional operation stations.

The monitoring window, operation interface, high-end CNC panel, wireless mouse and keyboard are integrated in the console. The device on/off, standby maintenance status, and startup operation can be completed on the same interface.

The device has built-in high-definition surveillance camera, real-time dynamic display of laser cutting whole process, equipment operation and machine running status monitoring can be considered at the same time.

It is equipped with a high-end CNC panel that conforms to the European and American operating standards. It also supports a convenient and simple mouse button operation mode to provide a variety of operating modes.

nLIGHT Fiber Lasers - high reflective metal cutting capability

nLIGHT Fiber Lasers have high-reflection material cutting performance, which can cut the high-reflection metals such as aluminum, brass, copper, gold and silver. The cutting performance of carbon steel and stainless steel is also outstanding.

nLIGHT Fiber Lasers have low failure rate and the module damage rate is almost zero, maintaining a long-term stable operation.

Technical Specifications of the Fiber Laser Cutting Machine

Model

GF-1530JH / GF-1560JH / GF-2040JH / GF-2060JH / GF-2560JH / GF-2580JH

Cutting area

1500mm×3000mm / 1500mm×6000mm / 2000mm×4000mm / 2000mm×6000mm / 2500mm×6000mm / 2500mm×8000mm

Laser source

IPG / nLight / Raycus fiber laser resonator

Laser power

1000W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W / 8000W / 10000W

Positioning accuracy

±0.03mm

Repeat positioning accuracy

±0.02mm

Maximum positioning speed

120m/min

Acceleration

1.5g

Electric power supply

AC380V 50/60Hz

Application of Fiber Laser Cutting Machine

Applicable Material

Carbon steel, mild steel, stainless steel, galvanized steel, alloy, titanium, aluminum, brass, copper and other metal sheets.

Applicable Industry

Sheet metal fabrication, machinery, electronics, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising signs, furniture, metal doors and railings, decoration, medical instruments, automotive parts, lamps, jewelry, glasses and other metal cutting fields.

Samples of Fiber Laser Cutting Metal Sheet