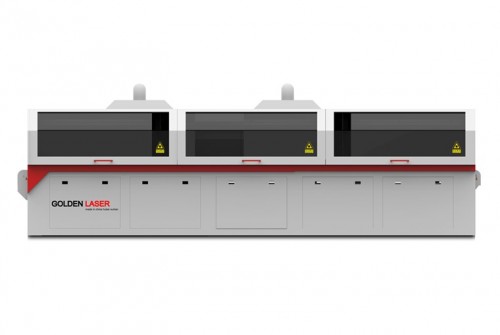

High Speed & High Precision CO2 Laser Cutting Machine

- Professional designed for filtration fabric industry

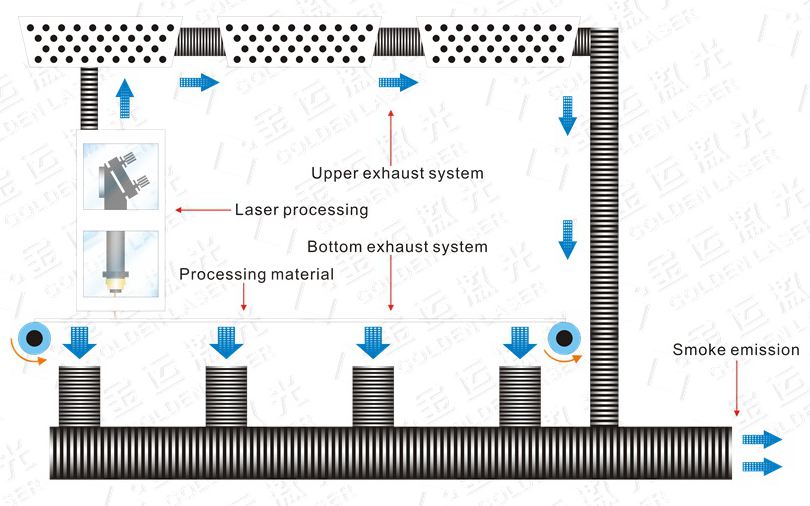

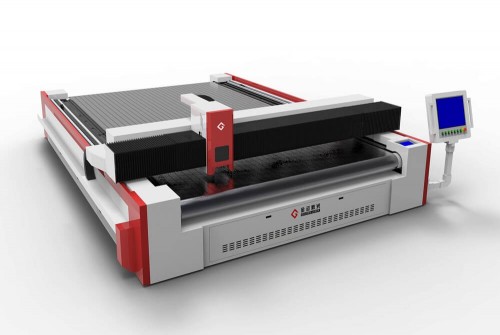

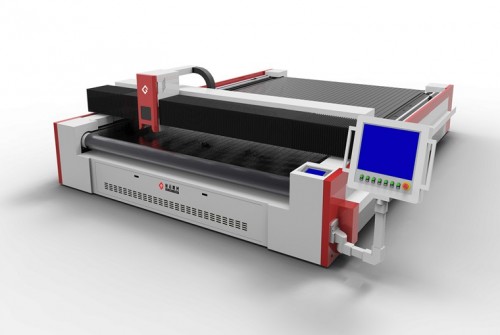

→ The large format CO2 laser cutting machine adopts a fully enclosed structure with a fully enclosed exhaust system to avoid secondary pollution of dust.

→ User-friendly wireless handle for remote operation.

→ High-precision gear & rack drive. 600 watt ~ 800 watt high-power CO2 metal RF laser.

→ The speed of laser head is up to 800mm/s, and the acceleration is up to 10000mm/s2, ensuring the high cutting efficiency and maintaining long-term stability.

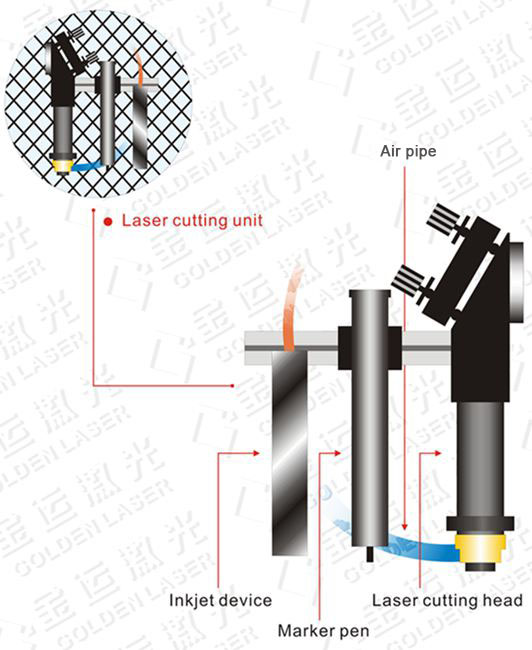

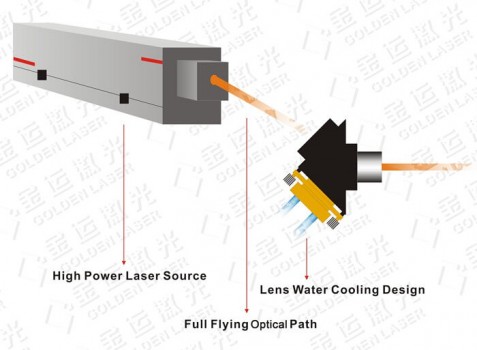

→ In order to ensure the fast movement of the laser head, the full-flying optical path structure is adopted, and water cooling for the lens is simultaneously performed to avoid damage of the lens by the high-power laser.

Automated production process

We manufacture laser cutting machine with high standards, expand multi-functions, configure automated feeding and winding systems, and develop flexible software. All in order to provide customers with higher production efficiency, more optimized production process, and maximize the benefits.

Automatic feeding device

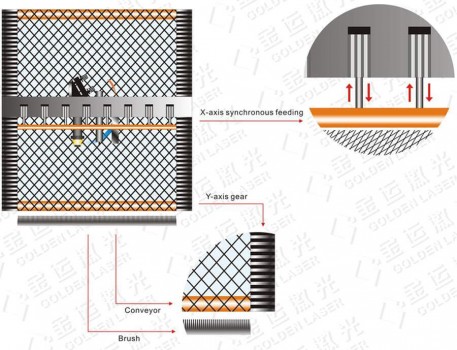

For flexible filter materials, the laser cutting machine uses special conveyor roller and specially designed X-axis synchronous feeding device to avoid the deviation of materials in the feeding process.

Equipped with receiving hopper to collect finished products.

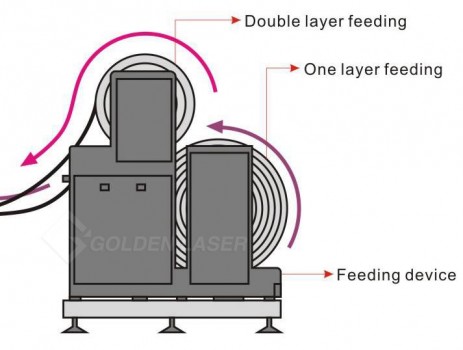

Double layer feeder

Double layer feeding device is customized for customers with double layer fabric processing requirements.

More configuration options

Technical Specifications of the Cutting Laser Machine

| Laser source | CO2 RF laser |

| Laser power | 150 watt / 300 watt / 600 watt / 800 watt |

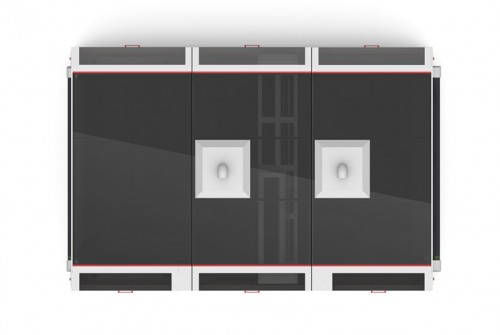

| Cutting area (W×L) | 2300mm×2300mm / 3000mm×3000mm (90.5” ×90.5” / 118”×118”) |

| Cutting table | Vacuum conveyor working table |

| Cutting speed | 0-1200mm/s |

| Acceleration | 10000mm/s2 |

| Repeating location | ≤0.05mm |

| Motion system | Offline mode servo motor motion system, High precision gear rack driving |

| Power supply | AC220V±5% / 50Hz |

| Format support | AI, BMP, PLT, DXF, DST |

Various working areas available:

2300mm×2300mm (90.5”×90.5”), 2500mm×3000mm(98.4”×118”), 3000mm×3000mm (118”×118”), 3500mm×4000mm (137.7” ×157.4”) Or other options.

The advantages of cutting filter cloth with laser

• Clean and perfect cut edges - no secondary processing required

• Automatic edge sealing due to laser thermal processing

• Extremely high precision in the laser cutting process - consistently high cutting quality

• Contactless laser cutting - no tool wear

• Virtually no dust formation during the laser cutting process

• High degree of flexibility - cutting any shapes and sizes, even making small holes, without any need for tool construction or changeover