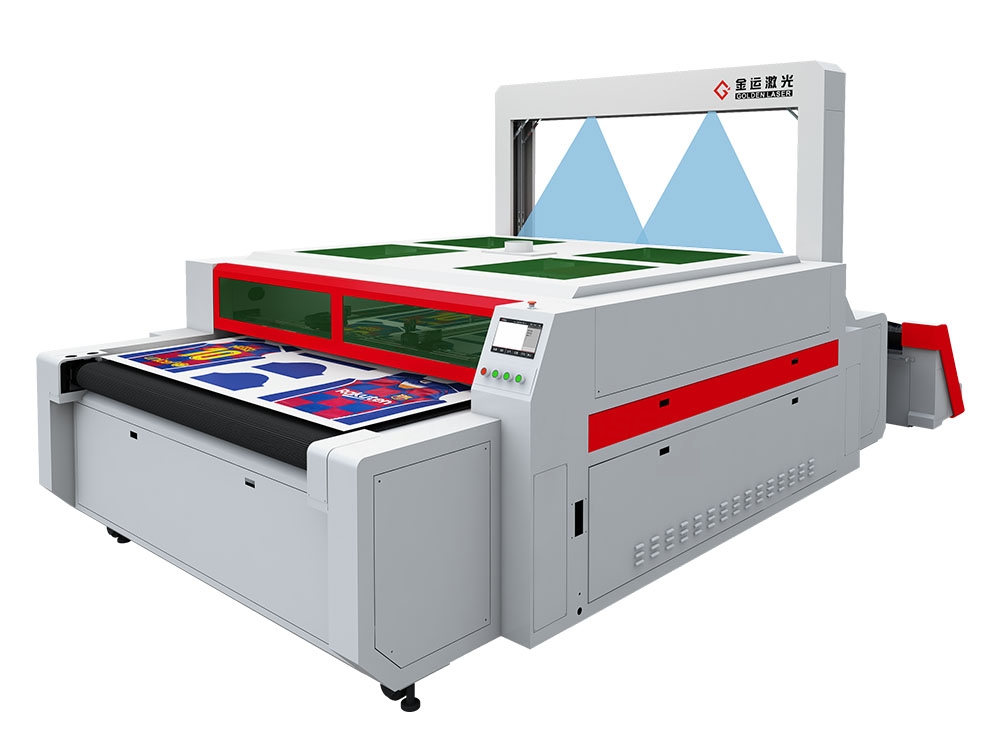

Vision laser cutting machine for dye-sublimation printed fabrics and textiles from a roll of nested printed shapes

Technical specifications of the laser cutting machine

| Working area | 1600mm×1300mm / 62.9"×51" |

| Camera scanning area | 1600mm×800mm / 62.9"×31.4" |

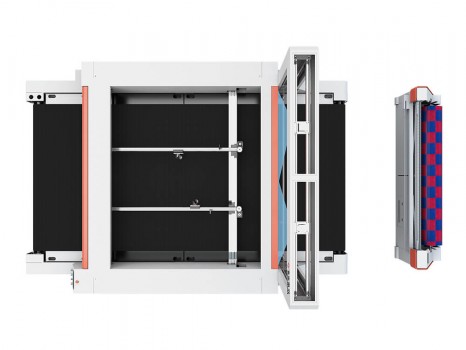

| Working table | Conveyor working table |

| Laser power | 70W / 100W / 150W |

| Laser tube | CO2 glass laser tube / CO2 RF metal laser tube |

| Control system | Servo motor system |

| Cooling system | Constant temperature water chiller |

| Exhaust system | 1.1KW exhaust fan×2, 550W exhaust fan×1 |

| Power supply | 220V 50Hz / 60Hz, single phase |

| Electrical standard | CE / FDA / CSA |

| Power consumption | 9KW |

| Software | Goldenlaser CAD scanning software package |

| Space occupation (with feeder) | 4316mm(L)×3239mm(W)×2046mm(H) (for reference only) |

| Other options | Auto feeder, red dot |

Fully automatic machining process for the vision scanning laser

WORK MODE 1 → Scan on the Fly

<< Step 1

Loading the sublimation printed fabric roll on the auto-feeder and conveyor working table of laser cutter.

Step 2 >>

HD Cameras scan the fabrics, detect and recognize the printed contour, and send the information to laser cutter.

<< Step 3

Set the cutting parameters. Press "start" button on laser cutter. Then the laser cutting machine will do cutting automatically.

Step 4 >>

Laser cutting and repeat the while process.

Advantages

Printing requirements

The printed outline and materials background have big color difference, distance not less than 5mm between the contours. Only the outer contour can be cut, the inside nested graphics cannot be cut.

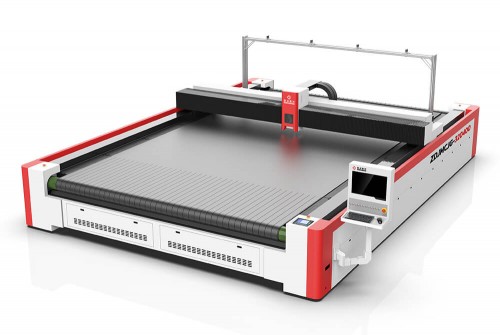

WORK MODE 2 → Scan print marks

Advantages

For soft materials easy to distort, curl, extended

For complicated pattern, nesting pattern inside the outline and high precision cutting requirement

Requirement

Need 1:1 original printed graphics file. Graphics format: *.jpg, *.bmp, or *.png