In order to protect the passengers, a variety of technologies and safety related devices are used in the car. For example, the body structure is designed to absorb impact energy. Even the recently popular Advanced Driver Assistance System (ADAS) has gone beyond the function of improving driving convenience and become an important configuration for safety. But the most basic and core safety protection configuration is seat belt and airbag. Since the formal application of automotive airbag in 1980s, it has saved countless lives. It is no exaggeration to say that airbag is the core of automobile safety system. Let’s take a look at the history and future of airbags.

In the process of vehicle driving, the airbag system detects an external impact, and its activation process has to go through several steps. First, the collision sensor of the components of the airbag system detects the strength of the collision, and the Sensor Diagnostic Module (SDM) determines whether to deploy the airbag based on the impact energy information detected by the sensor. If yes, the control signal is output to the airbag inflator. At this time, the chemical substances in the gas generator undergo a chemical reaction to produce high-pressure gas that is filled into the air bag hidden in the airbag assembly, so that the air bag instantly expands and unfolds. In order to prevent the occupants from hitting the steering wheel or dashboard, the entire process of airbag inflation and deployment must be completed in a very short time, about 0.03 to 0.05 seconds.

To ensure safety, continuous development of airbags

The first generation of airbags is in line with the intention of the early stage of technology development, that is, when an external collision occurs, the airbags are used to prevent the upper body of the passengers wearing seat belts from hitting the steering wheel or the dashboard. However, due to the high inflation pressure when the airbag is deployed, it may cause injury to small women or children.

After that, the defects of the first generation airbag were improved continuously, and the second generation decompression airbag system appeared. The decompression airbag reduces the inflation pressure (about 30%) of the first-generation airbag system and reduces the impact force generated when the airbag deploys. However, this type of airbag relatively reduces the protection of larger occupants, so the development of a new type of airbag that can compensate for this defect has become an urgent problem to be solved.

The third-generation airbag is also called “Dual Stage” airbag or “Smart” airbag. Its biggest feature is that its control method is changed according to the information detected by the sensor. Sensors equipped in the vehicle can detect whether the occupant is wearing a seat belt, external collision speed and other necessary information. The controller uses these information for comprehensive calculation, and adjusts the deployment time and expansion strength of the airbag.

Currently, the most widely used is the 4th generation Advanced airbag. Several sensors installed on the seat are used to detect the position of the occupant on the seat, as well as the detailed information of the occupant’s physique and weight, and use these information to calculate and determine whether to deploy the airbag and the expansion pressure, which greatly improves the protection of occupant safety.

From its appearance to the present, the airbag has been undisputedly evaluated as an irreplaceable occupant safety configuration. Various manufacturers have also been committed to the development of new technologies for airbags and continue to expand their scope of application. Even in the era of autonomous vehicles, airbags will always occupy the best position to protect the occupants.

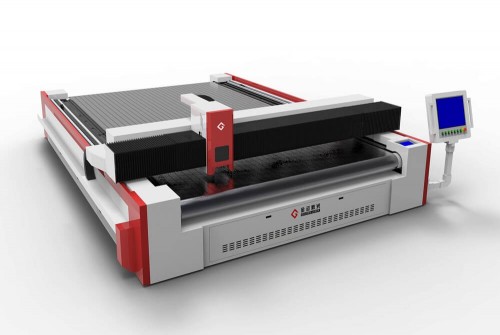

In order to meet the rapid growth of global demand for advanced airbag products, airbag suppliers are looking for airbag cutting equipment that can not only improve production capacity, but also meet strict cutting quality standards. More and more manufacturers choose laser cutting machine to cut airbags.

Laser cutting offers many advantages and allow high productivity: speed of production, very precise work, little or no deformation of the material, no tools required, no direct contact with the material, safety and process automation

Post time: Jan-12-2021