Textiles have always played an important role in different occasions and different applications. From simple protection from the cold to now used in home decoration, industrial filtration, automotive, insulation, and other industries, textiles begin to provide more functions beyond their own value. The research on textile materials and processing technology has given technical textiles more functions to meet the different needs of users.

According to data statistics, the market value of technical textiles in 2019 reached $201.2 billion and is estimated to grow rapidly at a compound annual growth rate of 5.1% in the following seven years. Such a huge market size and rapid growth rate indicate the development potential of the technical textile market, and also witness that consumer demand is changing. Antibacterial, anti-mildew, flame retardant, insulation, waterproof and other functions have been added to ordinary textiles. Textile manufacturers have gradually optimized their development strategies and changed their development directions to occupy a place in the textile market under the favorable conditions that technical textiles are popular and have broad prospects.

Which industries will steer the development of technical textiles in the future?

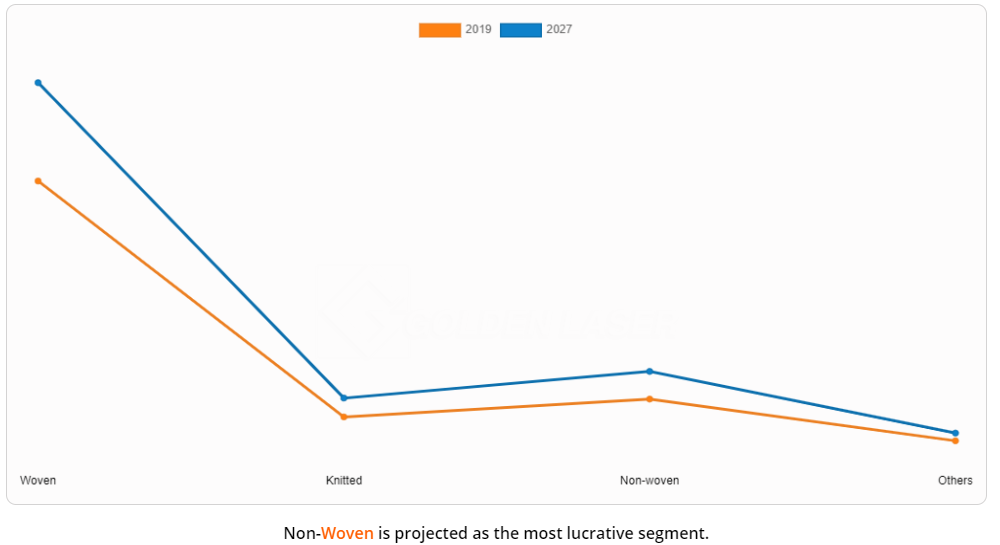

The current public’s attention to health care has greatly promoted the development of medical protective clothing. Face masks and protective clothing are not only adopted in the medical field but also widely used in daily life. Non-woven fabrics have become the preferred material for protective products due to their lightweight, breathability, good protective effect, durability, and environmental protection. The non-woven market is anticipated to develop rapidly in the next 7 years with a growth rate of 5.7%. This is why most textile manufacturers invest more funds in protective products.

Resource from: alliedmarketresearch

Resource from: alliedmarketresearch

In addition to the medical field, end users in the construction, filtration, packaging, and automotive industries are considered to have a major driving force for the development of future technical textiles. The prosperous development of these industries and the rapid rise of the vast emerging economies have provided a gradual expansion market for technical textiles.

Challenges faced and exploration of solutions

The technological advancement and material innovation of technical textiles have also injected a boost for manufacturers in this market despite the temporary disruption of the supply chain. However, facing the rapid development of the technical textile market and the emergence of more and more competitors, how to improve market competitiveness has become an urgent problem for technical textile manufacturers to think about. Moreover, the public’s attention to ecological issues has made environmentally friendly textile materials widely concerned. Based on this background, the control of raw material costs and the disposal of toxic wastes require technical textile manufacturers to find effective ways and strategies to solve them.

On the one hand, integration with the fashion industry may be a way for technical textile manufacturers to increase the added value of textiles. Digital printing, sublimation printing, and other technologies have been widely used in the field of apparel and home textiles, especially sportswear. Sportswear with multiple functions such as waterproof, quick-drying, and odor-resistant, with the support of sublimation printing technology, is suitable for outdoor or indoor sportsmen while providing safety guarantees, it also optimizes the wearing experience. On the other hand, technical textile manufacturers oriented to the industrial processing sector also need to seize opportunities, seek for high-quality partners, and innovate processing technologies to maintain market competitiveness.

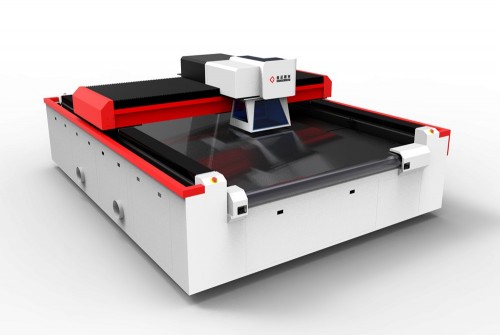

Application and advantages of laser cutting technical textiles

Whether it is home textiles, clothing, or industrial fabrics, technical textiles are the long-term development direction of these fields in the future. Laser cutting technology is creating growing revenue for these technical textile manufacturers. Owing to its high-precision cutting, timely edge banding, and high-degree of automation, laser cutting technical textiles has become an investment direction for more and more manufacturers.

It has always been goldenlaser‘s business philosophy to design customized and suitable laser processing solutions for customers to solve their worries. We are always available to help you if you are interested in laser cutting or want to consult laser-related issues. Please feel free to contact us!

Post time: Oct-18-2020