At CISMA2019, GOLDEN LASER has once again become the focus of the industry. GOLDEN LASER promotes the “Digital Laser Solution” that has been practiced for many years and is in line with CISMA2019′s “Smart Sewing Factory Technology and Solutions”. Among the exhibiting laser machines, there are “smart factories” that are suitable for the automated production requirements of large-volume orders; there are also “machining centers” that meet the needs of individualization, small batches, and rapid response.

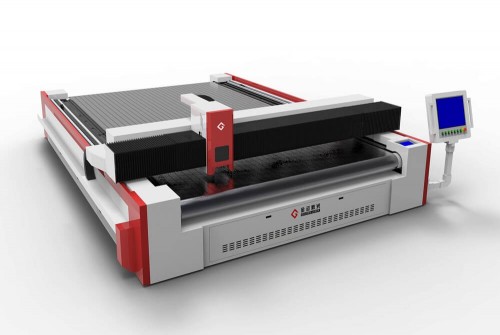

Part 1. JMC series laser cutting machine

The JMC series laser cutting machine exhibited at this exhibition is a high-performance CO2 laser cutting machine for industrial flexible materials (e.g. technical textiles and industrial fabrics) with high degree of automation. GOLDEN LASER has completed the delivery of several models with a maximum width of more than 3.5 meters. The laser cutting machine has the characteristics of high precision, high speed, maintenance-free, high protection, etc., and solves the problem of the flexible material feeding.

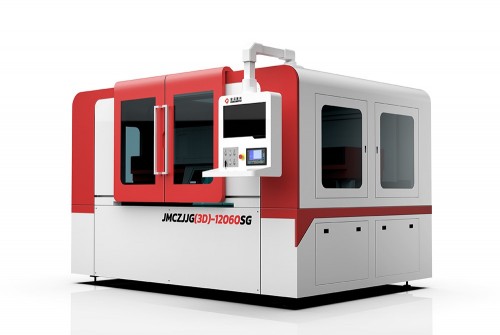

Part 2. SUPERLAB

With the development of the textile and garment industry, the application of new materials and the development of new processes are the focus of each brand’s research and development. The SUPERLAB we brought this time is a sharp tool for R&D and high-end personalized production. SUPERLAB not only integrates all the laser processing technology, but also has the functions of automatic calibration, auto focus, one-button processing, etc., which is very convenient and easy to use.

Part 3. The fifth generation “on-the-fly engraving cutting” series

On the CJSMA2019, the “on-the-fly engraving & cutting” of GOLDEN LASER was particularly favored. The laser system’s galvanometer scanning width is up to 1.8 meters and has a high precision vision system.

On-site demonstration of the garment lace is fully automatic slitting cutting, the processing speed is up to 400 m / h, and the daily processing capacity is over 8000 m, which can replace nearly one hundred labors.

In addition, this laser machine has no restriction on pattern, and it can finish the slitting and cutting at one time without the need for secondary processing. It surpasses the traditional laser equipment and is also the first lace laser cutting machine with the highest efficiency in China.

Part 4. Automatic cutting and collecting system

“Smart Factory” is inseparable from automation. For small pieces of textile such as shoes, hats and toys, GOLDEN LASER developed an automatic cutting and collecting system.

The system integrates the functions of automatic precise feeding, laser cutting and robotic sorting and palletizing, perfectly achieving assembly line production. With the MES system developed by GOLDEN LASER independently, unmanned workshops can be realized. The sorting system is suitable for various types of GOLDEN LASER’s laser cutting machines, laser marking machines and other models.

Part 5. Vision Scanning Laser Cutting Machine

Vision scanning laser cutting is the ace technology of GOLDEN LASER. The second-generation vision scanning laser cutting machine for dye-sublimation fabrics reduces the thermal diffusion effect of the laser on the edge of the material, and the cutting quality is greatly improved. At the same time, the vision system, material conveying system and cutting motion system are upgraded, making the cutting precision Higher, faster production, and better automation.

Part 6. Smart vision series

In the smart vision series, GOLDEN LASER offers a number of combinations. Single panoramic camera or dual industrial camera is optional. The camera system for embroidery patches and CAM vision system for digital printing can be added. Smart vision laser cutter is the necessary soft power of digital printing processing factory.

Nowadays, with the continuous advancement of “Industry 4.0″, “Internet”, and “Made in China 2025″, GOLDEN LASER takes “Made in China 2025″ as a strategic guide, focusing on the main line of intelligent manufacturing, and is determined to innovate and continue to exert strength and strive to achieve high quality development, providing more value-added products for downstream industries.

Post time: Sep-29-2019