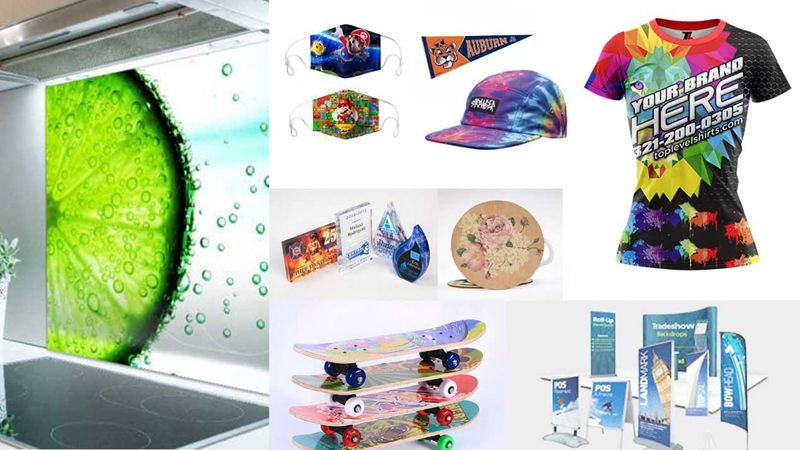

The technology of thermal transfer printing has been around for a long time. From its initial application in the field of clothing and footwear materials, now it has been widely used in all aspects of life in combination with digital printing technology, including apparel (sportswear, functional apparel), home textile & decoration, advertising banners, flags, decoration crafts (acrylic, wood, glass), medical supplies, electronics manufacturing, etc. Composed of two processes, printing and transfer, thermal transfer printing technology has gradually developed based on traditional plate printing. With the support of digital printing technology and the increasing demand for personalized products, emerging digital printing technology has gotten rid of the cumbersome process and the cost of plate-making, becoming the new favorite of the industry.

An outstanding representative of thermal transfer printing – sublimation printing

From the analysis of the printing and transfer process, both sublimation printers and ordinary inkjet printers can complete the printing process before transfer and transfer the ink from the paper to the substrate by sublimation transfer or thermal curing transfer. From the statistical point of view, sublimation transfer printing is one of the prominent representatives, and its market size is forecasted to grow to 1.0688 billion US dollars by 2028. The ink is sublimated to a gaseous state under heating and then diffused to the inside of the substrate instead of the surface under pressure. This inherent advantage contributes to the continuous and vivid color of the sublimation pattern, which is durable, heat-resistant, and waterproof.

The assistance of digital printing technology

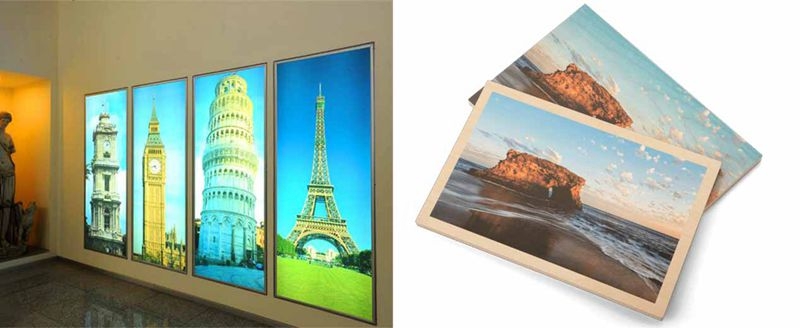

In the process of changing consumer demand, further subdividing industries to dig consumer demand points is a question that many manufacturers have been thinking about. The public’s pursuit of individualization has expanded the development space for the small-batch customization market, and digital printing technology has also emerged. Through digital pattern design, upload, and printing, consumers can transfer any pattern to a variety of substrates, including polyester fabrics, cotton fabrics, chemical fiber fabrics, leather, acrylic, wood, glass, ceramics, etc. In particular, the current functional fabrics and sportswear are much loved by everyone. The application of digital printing technology to these apparel fabrics can improve the sense of fashion and user confidence while ensuring a comfortable experience. In addition, digital printing technology for personalized customization is not restricted by design patterns and colors, and the production process is more flexible and changeable. It is the main force in the current and future printing market.

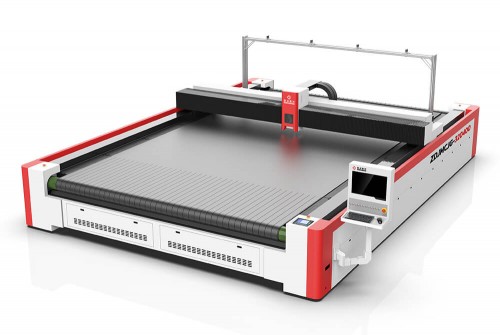

A good partner for heat transfer printing technology – laser cutting technology

When it comes to customized production, laser processing technology has to be mentioned. Suitable for customized processing and for cutting a variety of materials and patterns makes laser cutting technology and digital printing technology coincide. Laser cutting sublimation clothing and home textiles have been adopted as the main processing method by many textile fabric manufacturers. High cutting precision, timely edge sealing, no secondary processing, and high-efficiency and high-quality production are the unique advantages of laser processing. Also, laser cutting machines equipped with vision equipment can also automatically recognize the contour of various design patterns to achieve precise cutting.

Not only for apparel and home textiles, but laser cutting technology is also widely used in the field of outdoor advertising. Heat transfer printing banner, sublimation printing flag, printing billboard, printing rally pennant, printing poster can be accurately cut through the laser cutting machine. For outdoor advertising with high requirements for waterproof, sun protection, and durability, the combination of thermal transfer printing technology and laser processing technology can realize high-quality processing and provide manufacturers with long-lasting commercial value.

The combination of laser cutting technology and thermal transfer printing technology will greatly improve the production efficiency and processing quality for manufacturers, and create more commercial value.

Heat transfer printing acrylic, heat transfer printing wood, and other decorations, crafts can be contour recognized and precisely cut by laser. If you want to learn more about laser cutting heat transfer products or are interested in CO2 laser cutting and engraving systems, please feel free to contact us!

Post time: Oct-03-2020