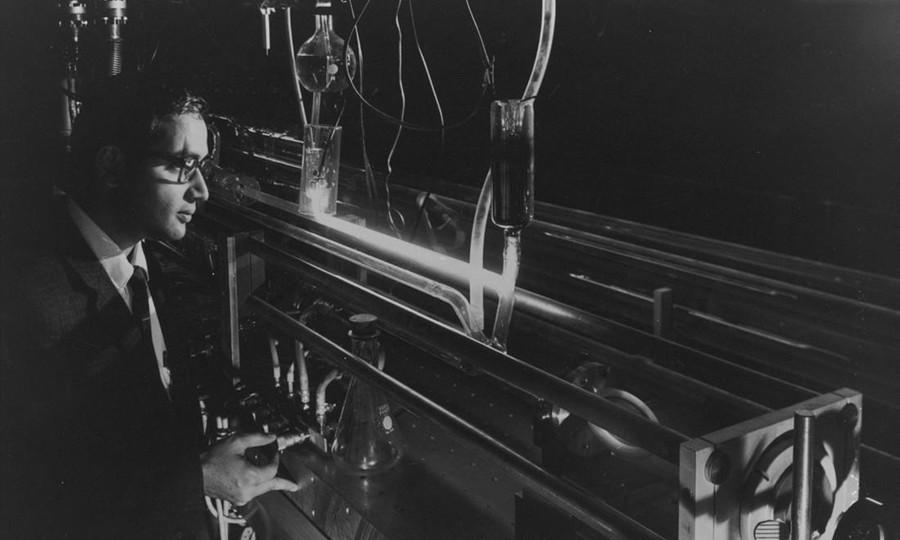

(Kumar Patel and one of the first CO2 laser cutters)

(Kumar Patel and one of the first CO2 laser cutters)

In 1963, Kumar Patel, at the Bell Labs, develops the first Carbon Dioxide Laser (CO2 laser). It is less costly and more efficient than the ruby laser, which has since made it the most popular industrial laser type – and it is the type of laser we use for our laser cutting machine. By 1967, CO2 lasers with power exceeding 1,000 watts were possible.

The uses of laser cutting, then and now

1965: Laser is used as a drilling tool

1967: First gas-assisted laser-cut

1969: First industrial use in Boeing factories

1979: 3D laser-cut

Laser cutting today

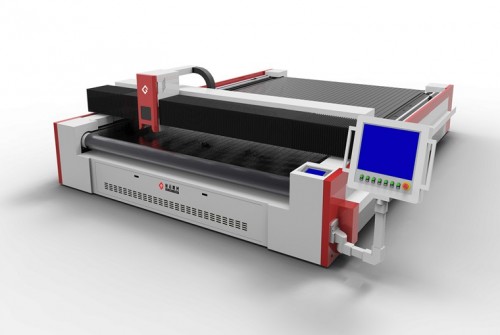

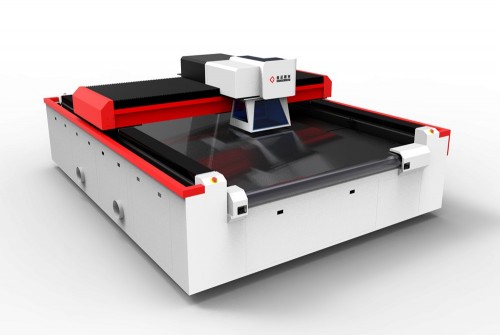

Forty years after the first CO2 laser cutting machine, laser-cutting is everywhere! And it’s not only for metals anymore: textile, leather, foam, acrylic, wood (plywood, MDF,…), paper, cardboard… Goldenlaser is providing lasers in good-quality and high-precision beams which not only can cut through nonmetal materials, with a clean and narrow kerf but also can engrave the patterns with very fine detail.

CO2 Laser Cutting Applications

CO2 Laser Cutting Applications

How laser cutting systems work?

Laser Cutting Systems use high powered lasers to vaporize material in the laser beam path; eliminating hand labor and other complicated extraction methods needed for small part scrap removal. Laser cutting is a tool-free process that uses vector-based digital images imported by operator software to direct the laser beam.

There are two basic designs for laser cutting systems: Gantry Systems and Galvanometer (Galvo) Systems:

1. Gantry Laser Cutting Systems are similar to XY Plotters. They physically direct the laser beam perpendicular to the material that is being cut; making the process inherently slow.

2. Galvanometer Laser Cutting Systems use mirror angles to reposition the laser beam in different directions; making the process relatively quick.

Why choose Laser Cutting?

Laser cutting is particularly effective in many areas where rapid production is essential. It’s easy to cut accurately in many materials where traditional manufacturing methods are inefficient. Limits and constraints imposed by traditional manufacturing processes are removed through Laser Cutting, which allows freedom of design and quantities.

Laser-cut opens up the field of possibilities in different industries! Engraving and perforation is also a frequent use for lasers. Goldenlaser has over 20 years’ experience focusing on laser application solutions in the fields of filter cloth, insulation materials, air dispersion, automotive & aviation, activewear & sportswear, outdoors & sporting goods, dye-sublimation printing, digital printing & labels.

Post time: Apr-09-2020