The continuous updating of textile fabrics has injected a steady stream of new vitality into the apparel market, home textile market and advertising market (especially sportswear and soft sign advertising industries). The prosperity of the textile industry and the public’s individual pursuit of aesthetics and fashion has given birth to new printing technologies to realize the printing of diverse styles and patterns that are difficult to achieve by traditional printing. The emergence of sublimation printing technology has met this consumer demand and market gap.

The global dye sublimation market is developing rapidly and is predicted to grow at a compound annual growth rate of 10.7% in the next five years. This is fortunate for manufacturers in the apparel field, which occupy a large share of the market. More and more manufacturers have begun to embrace dye sublimation printing technology in order to increase production efficiency and quickly seize the market.

What are the advantages of dye sublimation printing technology is favored by manufacturers who use textile fabrics as raw materials?

The characteristics of sublimation printing technology itself:

1. Compared with traditional ink printing technology, sublimation printing technology is a continuous tone printing technology that produces natural and smooth color gradients by mixing the three main colors of pigments, so it can present realistic visual effects on clothing or advertising.

2. The sublimation printer will not have ink residue during the printing process because the thermal head of the printer does not need to move back and forth to transfer the ink to the printing carrier.

3. Different from screen printing and direct printing, dye sublimation printing technology injects dyes into the printing matrix at the molecular level, which fundamentally determines the long-term retention of colors and patterns and the characteristics of washing and abrasion resistance.

Wide ranges of applications

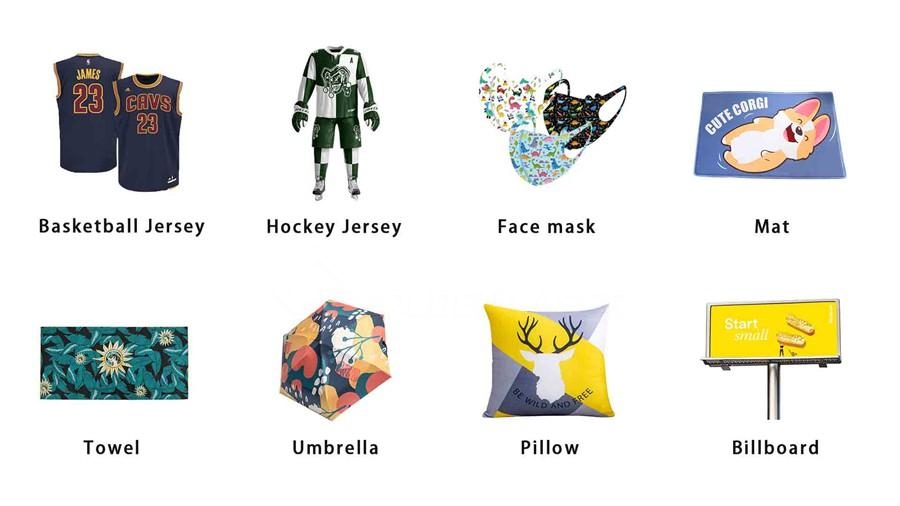

As we know, home textiles are mostly decorated with colorful printing to create a home environment full of vitality, which provides a broad market and development space for dye sublimation printing technology. In addition, dye-sublimation printing technology also plays an important role in the field of clothing, especially in the sportswear industry with polyester fiber as the main raw material, because polyester fabrics are the most ideal textile carriers for sublimation printing. Specifically, the curtains, quilts, pillows, wallpapers, banners, towels, yoga clothes, jerseys, and sweatshirts in our daily life have almost all traces of sublimation printing.

Technology maturity and declining cost

The pursuit of color richness has prompted the deepening of research on sublimation inks. Some brands have introduced fluorescent inks and transferred them to textile materials to broaden the color richness to create distinctive styles. And the technical research of dye-sublimation printers is also continuing to follow the ever-increasing diversified needs, whether it is printing speed or printing format. The maturity of the technology and the widespread application have brought about a gradual reduction in costs, which makes manufacturers more willing to apply dye sublimation printing technology in production as a powerful means to expand the market.

What equipment does the sublimation printing technology involve?

For some manufacturers, the principle of dye sublimation printing technology is not unfamiliar. As far as the dye-sublimation printing of textile fabric is concerned, the dye is directly sublimated from solid to gas and then enters the fabric to bond with the fabric fiber to obtain a long-lasting and realistic visual effect. In order to obtain better printing results, manufacturers who apply dye sublimation printing technology to clothing, home textiles, and advertising production not only need to select specific inks but also need suitable equipment.

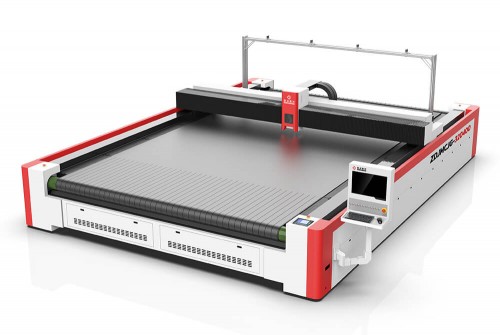

Dye sublimation printers and heat presses are essential equipment in the printing process. Besides, the selection of suitable cutting equipment also determines the quality of the printed product and the efficiency of the entire production process. In terms of dye-sublimation printed fabrics, laser cutting machine can be said to be the most ideal processing tool because it can be equipped with a visual camera to recognize the contour of the printed pattern to ensure the accuracy of fabric cutting. Moreover, thermal processing can seal the edges in time to achieve a clean and smooth edge effect, without secondary processing, which greatly improves production efficiency and shortens the production cycle. The high degree of automation is also one of the reasons for the popularity of laser cutting equipment. The reduction of labor and time costs and the extremely low rate of defective products improve efficiency for manufacturers while ensuring the high quality of products, greatly improving production revenue and brand popularity.

Laser cutting machine for sublimation printing fabrics, including clothing, billboards, and home textiles is definitely the optimal choice. And laser cutting technology and dye sublimation printing technology have been used by many manufacturers in the production process with the maturity of laser technology and the reduction of the purchase cost. Goldenlaser is a laser equipment manufacturer with more than 20 years of production experience. It is our consistent aim to provide customers with the most suitable laser equipment solutions and high-quality services. Your puzzle, we care.

If you want to know more about laser cutting of sublimation apparel and laser cutting of print advertising, please feel free to contact us!

Post time: Sep-21-2020