2020 is a turbulent year for global economic development, social employment and manufacturing, as the world is struggling to deal with the impact of COVID-19. However, crisis and opportunity are two sides, and we are still optimistic about some things, especially manufacturing.

Although 60% of manufacturers feel that they have been affected by COVID-19, a recent survey of senior leaders of manufacturers and distribution companies shows that their company revenues have increased significantly or appropriately during the epidemic. The demand for products has surged, and companies urgently need new and innovative production methods. Instead, many manufacturers have survived and changed.

With 2020 coming to an end, the manufacturing industry around the world is undergoing tremendous changes. It has promoted the development of the manufacturing supply chain unprecedentedly. It has inspired stagnant industries to act and respond to the market faster than ever.

Therefore, in 2021, a more flexible manufacturing industry will emerge. The following are our beliefs that the manufacturing industry will seek better development in these five ways next year. Some of these have been brewing for a long time, and some are due to the epidemic.

1. Shift to local production

In 2021, the manufacturing industry will shift to localized production. This is mainly caused by ongoing trade wars, tariff threats, global supply chain pressures, etc., encouraging manufacturers to move production closer to customers.

In the future, manufacturers will want to build production where they sell. The reasons are as follows: 1. Faster time to market, 2. Lower operating capital, 3. Government policies and more flexible response efficiency. Of course, this will not be a simple one-shot change.

The larger the manufacturer, the longer the transition process and the higher the cost, but the challenges of 2020 make it more urgent to adopt this production method.

2. The digital transformation of factories will accelerate

The epidemic reminded manufacturers that relying on human labor, physical space, and centralized factories located around the world to produce goods is very fragile.

Fortunately, advanced technologies – sensors, machine learning, computer vision, robotics, cloud computing, edge computing, and 5G network infrastructure – have been proven to improve manufacturers’ supply chain resilience. Although this poses a series of challenges for the production line, technology companies will focus on empowering the application value of advanced technologies into a vertical production environment in the future. Because the manufacturing industry must diversify its factories and embrace Industry 4.0 technology in order to increase its resilience against risks.

3. Facing increasing consumer expectations

According to eMarketer data, American consumers will spend approximately US$710 billion on e-commerce in 2020, which is equivalent to an annual growth of 18%. With the surge in product demand, manufacturers will face greater pressure. This allows them to produce high-quality products faster, more efficiently, and at lower cost than ever before.

In addition to shopping behavior, we have also seen a shift in the relationship between manufacturers and customers. Broadly speaking, this year’s customer service has developed by leaps and bounds, and companies prioritize personalized experience, transparency and rapid response. Customers have become accustomed to this type of service and will ask their manufacturing partners to provide the same experience.

From the results of these changes, we will see more manufacturers accept low-volume manufacturing, completely transform from mass production, and pay more attention to data-driven insights and product experience.

4. We will see an increase in investment in labor

Although the news reports on the replacement of automation in the past few years have been extensive, automation is not only replacing existing jobs, but also creating new jobs.

In the era of artificial intelligence, as production gets closer and closer to consumers, advanced technology and machines have become the main force in factories and workshops. We will see manufacturers take more responsibilities in this transition – to create higher-value and higher-paying jobs for employees.

5. Sustainability will become a selling point, not an afterthought

For a long time, manufacturing industry has been one of the main causes of environmental pollution.

As more and more countries put science and the environment first, it is expected that in the future, the manufacturing industry will strive to implement efficiency reforms in creating green jobs and reducing a large amount of waste in the industry, so that enterprises will become more sustainable.

This will give birth to a distributed network of small, local and energy-efficient factories. This combined network can reduce energy consumption, reduce waste, and reduce the overall carbon emissions of the industry by shortening transportation routes to customers.

In the final analysis, the manufacturing industry is a continuously evolving industry, although historically, this change has mostly been “slow and stable.” But with the advancement and stimulus in 2020, in the manufacturing industry in 2021, we will begin to see the evolution of an industry that is more sensitive and adaptable to the market and consumers.

Who Are We

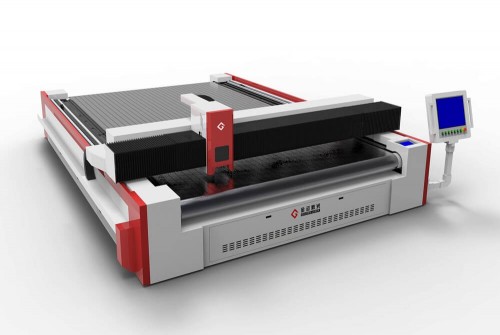

Goldenlaser is engaged in the design and development of laser machines for cutting, engraving and perforation. Our CO2 laser cutting machines, CO2 Glavo laser machines and fiber laser cutting machines stand out with their advanced technologies, structure design, high efficiency, speed and stability, meeting various needs for our esteemed customers.

We listen, understand and respond to our customers’ needs. This enables us to use our depth of experience and our technical and engineering expertise to equip them with powerful solutions to their most pressing challenges.

We provide digital, automated and intelligent laser application solutions to help traditional industrial production upgrade to innovation and development. Our 20-year expertise and experience of laser solutions deeply rooted in the technical textiles, automotive & aviation, fashion & apparel, digital printing, and filter cloth industry allows us to accelerate your business from strategy to day-to-day execution.

Post time: Dec-07-2020