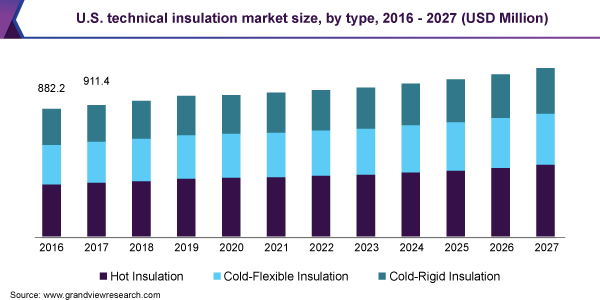

According to the latest research report, the compound annual growth rate of the global technical insulation market will reach 2.5% in the next 7 years. The rapid development of the technical insulation market is caused by various factors.

The lower cost of insulating materials makes it widely used in a variety of industries, especially in the industrial production process, insulated pipes and equipment are the most used to ensure the high efficiency of heat transfer and the excellent performance of the machine. Moreover, the deepening of the concept of sustainability and the development of technologies that limit energy losses have promoted the development of the technical insulation market. Besides, more stringent regulations have further limited the energy consumption in the industrial sector.

The insulation markets in Europe, America, and the Asia Pacific occupy an important position in the global technical insulation market. For Europe, emerging industries and OEMs have great demand for heating piping systems, refrigeration systems, and acoustic insulation systems, which has greatly promoted the booming development of the insulation market. The compound annual growth rate of the United States is expected to reach 2.3% in the next 7 years, which is due to the expansion of industrial and commercial fields and the wide application of insulation materials in industrial, commercial, and household fields. In addition, the massive construction of infrastructure has further promoted the development of the technical insulation market in the Asia-Pacific region. Not only that, population growth and industrialization, and the accelerated development of urbanization have also brought huge growth space for the development of the insulation market so that the region is expected to grow at a compound annual growth rate of 3.0% in the next 7 years.

The wide variety of insulating materials provides multiple choices for applications such as thermal insulation, cold insulation, and sound insulation. Thermal insulation is generally used in chemical plants and oil refineries. In order to reduce energy consumption and improve production efficiency, the factory will use heavy insulation materials to wrap the transportation pipeline. The food processing industry uses more insulating materials for cold insulation to ensure the low-temperature storage and freshness of food. Shopping malls and office spaces have higher requirements for the sound insulation of insulation materials. These increasing demands have in turn stimulated the development of the technical insulation market.

Fiberglass, Mineral Wool, Cellulose, Natural fibers, Polystyrene, Polyisocyanurate, Polyurethane, Vermiculite and Perlite, Urea-formaldehyde Foam, Cementitious Foam, Phenolic Foam, and many other insulation materials are widely used in the technical insulation market. A variety of materials are suitable for a variety of insulation applications, so it is necessary to find a more flexible and versatile processing method.

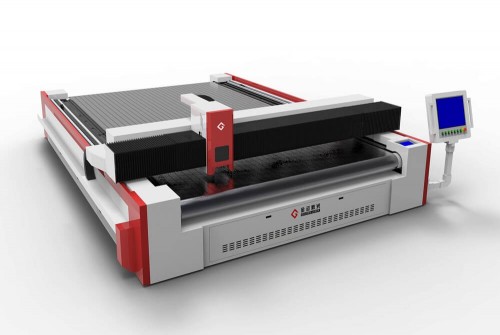

Laser processing is a good choice, suitable for a variety of materials. Not only that, but laser cutting machine also has the characteristics of high processing accuracy, high automation, and cost-effectiveness, which can effectively meet the needs of the growing insulation market. Goldenlaser has been committed to laser research and production for more than 20 years. We are willing to provide high-quality and suitable services if you are looking for insulation materials processing solution or want to learn more about laser cutting insulation materials. Please contact us!

Post time: Sep-14-2020