With the rapid development and wide application of the industrial air filtration market, the advantages of laser cutting filter materials have gradually emerged. Maximizing production efficiency and being suitable for cutting a variety of materials and shapes make laser cutting a more ideal processing method!

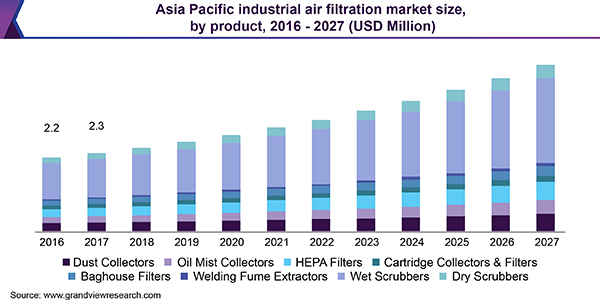

According to market statistics, the global industrial air filtration market will reach a compound annual growth rate of 7.3% in the next seven years. With the increasing attention to environmental protection and health and the increasing demand for reducing energy consumption, the industrial air filtration industry is developing faster and faster. And for manufacturers in many industries, the reduction of natural resources makes the supply of raw materials in short. It is a very popular way to maximize the utilization rate of raw materials through the filtration system. In addition, the promulgation of relevant laws and regulations and technological progress have promoted the development of the industrial air filtration industry.

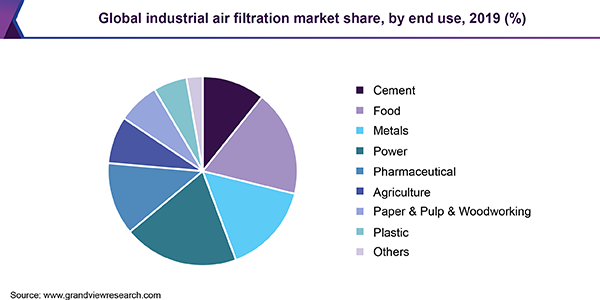

Resource from Grand View Research

Industrial air filtration systems are widely used in cement, food, metal, and other industries. In terms of regions, Europe has a 27% industrial air filtration market share in 2019, and it is predicted to maintain steady growth in the next few years. Secondly, the industrial air filtration market in the Asia-Pacific region has also continued to grow due to the rapid development of industrialization and the increase in per capita income.

In summary, the industrial air filtration market has broad prospects and huge development potential. Due to strict exhaust emission standards and expensive filter materials, manufacturers need to find better processing methods to maximize production efficiency. Better processing methods can not only improve efficiency but also reduce costs. Laser processing is one of the great choices. The following are the advantages of laser cutting filter materials to help to improve yield and quality.

1. High level of precision and accuracy of repeatability during cutting

2. Clean and perfect edges due to thermal laser processing

3. Cutting almost all filter materials and any shapes

Laser cutting is suitable for a variety of air filter materials, such as polyurethane, polyester, activated carbon, polypropylene, and other materials and it can be customized according to different shapes and sizes needs. Goldenlaser can provide you with the most suitable processing solutions for filter materials on account of 20 years of experience for providing laser solutions. Welcome to your inquiry.

Post time: Aug-17-2020