Uhlaziyo oluqhubekayo lwelaphu elilukiweyo luye lwafaka uthotho oluzinzileyo lokuqina okutsha kwimakethi yempahla, kwimakethi yamalaphu asekhaya kunye nentengiso yentengiso (ingakumbi.iimpahla zezemidlalo kunye neempawu ezithambileyo zentengiso kumashishini).Ukuchuma koshishino lwamalaphu kunye nokusukelwa komntu ngamnye kobuhle kunye nefashoni kuye kwazala ubugcisa obutsha bokuprinta ukuqonda ukushicilelwa kweendlela ezahlukeneyo kunye neepateni ekunzima ukuzifumana ngoshicilelo lwemveli.Ukuvela kweushicilelo lwe-sublimationiteknoloji iye yahlangabezana nale mfuno yabathengi kunye nomsantsa wemarike.

Imakethi yehlabathi ye-sublimation yedayi ikhula ngokukhawuleza kwaye kuqikelelwa ukuba iya kukhula ngesantya sonyaka sokukhula nge-10.7% kule minyaka mihlanu izayo.Eli lithamsanqa kubavelisi kwibala lempahla, elithatha isabelo esikhulu semarike.Bayanda abavelisi sele beqalisile ukwamkela itekhnoloji yoshicilelo lwedayi ye-sublimation ukwenzela ukwandisa ukusebenza kakuhle kwemveliso kwaye babambe ngokukhawuleza imarike.

Zeziphi iingenelo zetekhnoloji yoshicilelo lwedayi sublimation ethandwa ngabavelisi abasebenzisa amalaphu elaphu njengemathiriyeli ekrwada?

Iimpawu zeteknoloji yoshicilelo lwe-sublimation ngokwayo:

1. Xa kuthelekiswa neteknoloji yoshicilelo lwe-inki yendabuko, iteknoloji yokushicilela i-sublimation iteknoloji yokushicilela ithoni eqhubekayo evelisa i-gradients yendalo kunye nombala ogudileyo ngokuxuba imibala emithathu ephambili yee-pigments, ngoko inokubonisa iziphumo ezibonakalayo ezibonakalayo kwiimpahla okanye kwintengiso.

2. Umshicileli we-sublimation akayi kuba nentsalela ye-inki ngexesha lenkqubo yokuprinta kuba akukho mfuneko yokuba intloko ye-thermal yomshicileli ihlehle ngapha nangapha ukuze idlulisele i-inki kumthuthi wokuprinta.

3. Ihluke kwi-screen printing kunye nokuprinta ngokuthe ngqo, iteknoloji yokushicilela i-sublimation yedayi ifaka iidayi kwi-matrix yokushicilela kwinqanaba le-molecular, elimisela ngokusisiseko ukugcinwa kwexesha elide lemibala kunye neepatheni kunye neempawu zokuhlamba kunye nokuxhatshazwa kwe-abrasion.

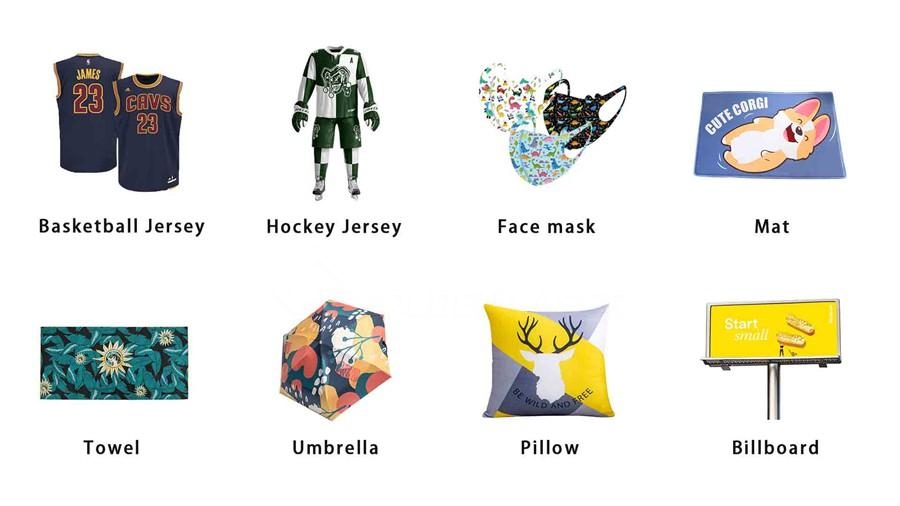

Uluhlu olubanzi lwezicelo

Njengoko sisazi, amalaphu asekhaya ahonjiswe ubukhulu becala ngoshicilelo olumibalabala ukudala imeko-bume yekhaya egcwele amandla, ebonelela ngemarike ebanzi kunye nesithuba sophuhliso lwetekhnoloji yoshicilelo lwedayi sublimation.Ukongeza, itekhnoloji yokuprinta idayi-sublimation nayo idlala indima ebalulekileyo kwibala lempahla, ngakumbi kwishishini lezemidlalo kunye nefiber yepolyester njengeyona nto iphambili, kuba amalaphu e-polyester awona afanelekileyo abathwali belaphu ukuprintwa kwe-sublimation.Ngokukodwa, iiikhethini, iileyile, imiqamelo, amaphephadonga, iibhena, iitawuli, iimpahla zeyoga, iijezi, kunye nezikipakubomi bethu bemihla ngemihla phantse yonke imikhondo yoshicilelo lwe-sublimation.

Ukuvuthwa kweTekhnoloji kunye nokwehla kweendleko

Ukusukela ukutyeba kombala kuye kwabangela ukujula kophando kwii-inki ze-sublimation.Ezinye iibrendi ziye zazisa ii-inks ze-fluorescent kwaye zazidlulisela kwimathiriyeli yelaphu ukwandisa ukutyeba kombala ukwenza izitayile ezahlukileyo.Kwaye uphando lobuchwephesha lwabashicileli bedayi-sublimation luyaqhubeka nokulandela iimfuno ezihlala zisanda ngokwahlukeneyo, nokuba sisantya soshicilelo okanye ifomathi yoshicilelo.Ukuvuthwa kwethekhnoloji kunye nesicelo esibanzi kwazisa ukuncitshiswa kancinci kweendleko, okwenza abavelisi bazimisele ngakumbi ukusebenzisa iteknoloji yoshicilelo lwedayi sublimation kwimveliso njengendlela enamandla yokwandisa imarike.

Zeziphi izixhobo ezibandakanya iteknoloji yoshicilelo lwe-sublimation?

Kwabanye abavelisi, umgaqo wokushicilela iteknoloji yedayi sublimation ayiqhelekanga.Ngokubhekiselele kwidayi-sublimation yoshicilelo lwelaphu elilukiweyo, idayi ithotywa ngokuthe ngqo ukusuka eqinileyo ukuya kwirhasi kwaye emva koko ingene kwilaphu ukuze idibane nefayibha yelaphu ukufumana isiphumo esibonakalayo esihlala ixesha elide nesinokwenyani.Ukuze bafumane iziphumo ezilunge ngakumbi zokuprinta, abavelisi abasebenzisa ubugcisa bokushicilela bedayi ethambileyo kwimpahla, kwilaphu lasekhaya, nakwimveliso yentengiso abafuni nje ukukhetha ii-inki ezithile kodwa bakwafuna nezixhobo ezifanelekileyo.

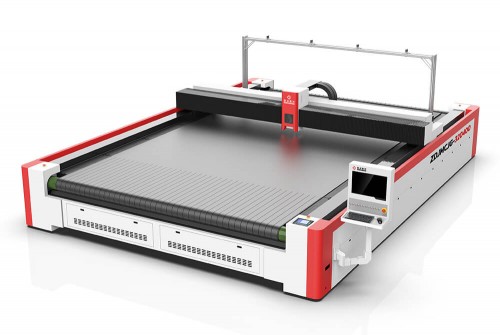

Iiprinta ze-Dayi sublimation kunye noshicilelo lobushushu zizixhobo ezibalulekileyo kwinkqubo yoshicilelo.Ngaphandle koko, ukukhethwa kwezixhobo ezifanelekileyo zokusika kwakhona kumisela umgangatho wemveliso eprintiweyo kunye nokusebenza kakuhle kwayo yonke inkqubo yokuvelisa.Ngokubhekiselele kwidayi-sublimation eprintiweyo amalaphu, umatshini wokusika we-laser unokuthiwa yeyona nto ifanelekileyo yokulungisa isixhobo kuba inokuxhotyiswa ngekhamera ebonakalayo ukuze ibone i-contour yepateni eprintiweyo ukuqinisekisa ukuchaneka kokusikwa kwelaphu.Ngaphezu koko, ukusetyenzwa kwe-thermal kunokutywina imiphetho kwangexesha ukufezekisa isiphumo esicocekileyo nesigudileyo somphetho, ngaphandle kokulungiswa kwesibini, okuphucula kakhulu ukusebenza kakuhle kwemveliso kunye nokunciphisa umjikelo wemveliso.Iqondo eliphezulu lokuzenzekelayo sesinye sezizathu zokuthandwa kwezixhobo zokusika i-laser.Ukuncitshiswa kweendleko zabasebenzi kunye nexesha kunye nezinga eliphantsi kakhulu leemveliso ezineziphene kuphucula ukusebenza kakuhle kubavelisi ngelixa uqinisekisa umgangatho ophezulu weemveliso, ukuphucula kakhulu ingeniso yemveliso kunye nokuthandwa kophawu.

Umatshini wokusika weLaser weempahla zokuprinta i-sublimation, kubandakanywa iimpahla, iibhodi zebhilibhodi, kunye namalaphu asekhaya ngokuqinisekileyo lolona khetho lufanelekileyo.Kwaye iteknoloji yokusika i-laser kunye ne-dayi sublimation yokushicilela iteknoloji isetyenziswe ngabavelisi abaninzi kwinkqubo yokuvelisa kunye nokuvuthwa kobuchwepheshe be-laser kunye nokunciphisa iindleko zokuthenga.I-Goldenlaser ngumvelisi wezixhobo ze-laser oneminyaka engaphezu kwama-20 yamava okuvelisa.Yinjongo yethu engaguqukiyo ukubonelela abathengi ngezona zisombululo zezixhobo ze-laser ezifanelekileyo kunye neenkonzo ezikumgangatho ophezulu.Iphazili yakho, siyakhathala.

Ukuba ufuna ukwazi ngakumbi malungaukusika kwe-laser kwempahla ye-sublimationkwayelaser cut of print intengiso, nceda uzive ukhululekile ukuqhagamshelana nathi!

Ixesha lokuposa: Sep-21-2020