Inguquko yokuphrinta yedijithali ishintshe kakhulu indawo yokudalwa kwamalebula.

Ngokuguquguquka kwedizayini ephrintiwe, isidingo sokushintsha kalula umumo osikiwe ukuze uhambisane sesibaluleke kakhulu.Ngokwesiko, ukusika kwenziwa ngomshini wokunyathelisa wokufa kanye nezihlikihli zommese, lapho umsebenzisi ekhiyelwa edizayini eyodwa ukuze kushintshwe ukukhiqiza.Izindleko nokusetshenziswa okuyinkimbinkimbi kokugcina ama-dies amaningi kwenza kungenzeki ukuba nezimo eziningi ezisikiwe ezitholakalayo.

Ngaphezu kwalokho, isikhathi sokuphumula esihlobene nezinguquko zamathuluzi sehlisa amamethrikhi okukhiqiza, okuvamise ukuba yisici esinqumayo kuzo zonke izindleko zokusebenza.Ukusika i-laser ngamakhanda okuskena ngesivinini esikhulu kuye kwashintsha lokhu kwaba inqubo eguquguqukayo futhi eguquguquka kalula, lapho izinguquko zedizayini ezisikiwe zingenziwa ngokundiza nge-software ngaphandle kokumisa umugqa wokukhiqiza.Inguquko yokuphrinta yedijithali ingenisa isidingo sokucutshungulwa kwe-laser ngoba iwubuchwepheshe obufanele bokukhiqiza imisebenzi yesikhashana, yangokwezifiso.

Izinzuzo zokuguqulwa kwe-laser ziningi.

Ngaphezu kokuvumelana nezimo kwedijithali kwedizayini entsha engashintshwa ngokuhamba kwesikhathi, ezinye izinzuzo ezinjengokuthuthukiswa kwesivuno ezitholakala endleleni yokungaxhumani naye akumele zishaywe indiva, ikakhulukazi njengoba amalebula eba mancane futhi enekhono lokukhetha "lokusikwa-kiss". " ekujuleni okulawulwayo.Futhi, ukucubungula okusekelwe nge-laser akunakho okusebenzisekayo (okungukuthi, awekho amathuluzi emishini agugile) futhi kunikeza imiphumela ephindaphindwayo (ama-laser awatholi buthuntu).Ngenxa yalezi zizathu, izinzuzo zokusebenza ezinikezwa ubuchwepheshe obususelwa ku-laser, idijithali, obungathintani nabo buphoqa.

Isistimu ye-modular yangempela enezinketho zokuguqula ezitholakalayo

ISIKHATHI SOKUyisa IBHIZINISI LAKHO LEBHIZINISI PHAMBILI!

Lamination / UV Varnishing / Cold Foil / Laser Cutting / Perforating / Etching / Scoring / Hot Stamping / Flat Bed Die Cutting / Semi Rotary Die Cutting / Waste Rewind / Slitting ...

Yiziphi izinzuzo zomshini wokusika we-laser we-Goldenlaserukuze amalebula aqedele?

DIGITAL LASER IZIXAZULULO ZAMALEBHU

Izinkambu Zokusebenza

Izinhlelo zokuguqula i-laser ze-Goldenlaser zinikeze amakhasimende ethu amathuba ezimakethe ezintsha nezikhona, njenge:

Isincomo somkhiqizo

I-Goldenlaser isungule amasistimu okusika amalebula e-laser omkhakha wokulebula nokupakisha.Khetha umkhiqizo ozifanela kangcono izidingo zakho, bese usithinta ukuze uthole iseluleko.

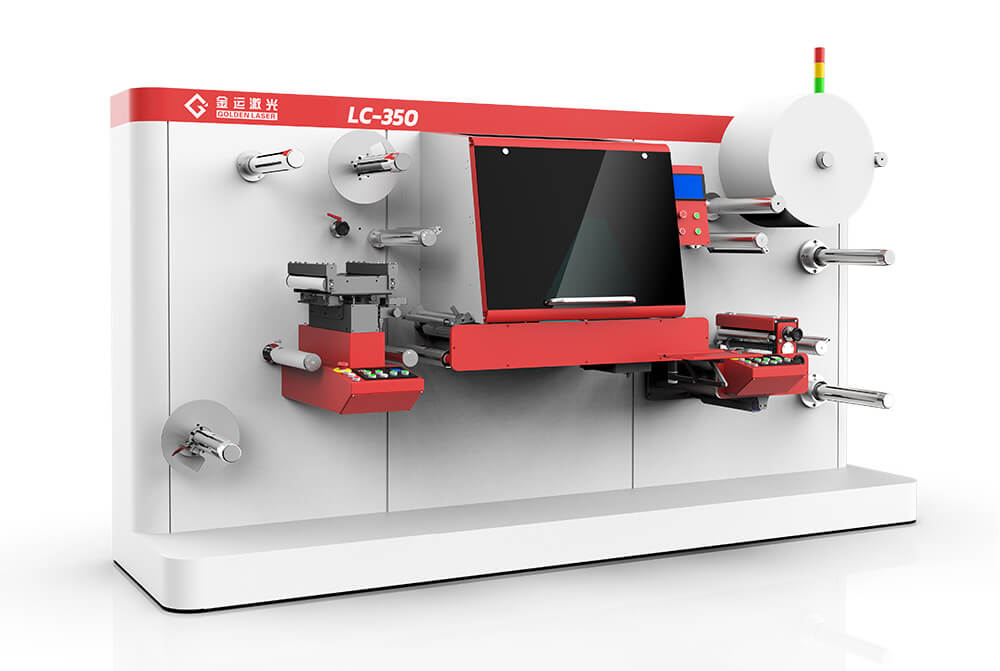

I-LC350Ukuqedwa kwedijithali ngekhanda lokusika le-laser elilodwa noma elikabili

Umshini wokusika we-laser unokuguquguquka kokwenziwa ngezifiso ngezinketho ezahlukene zokuguqula ukuze uthuthukise imikhiqizo yakho futhi unikeze ukusebenza kahle emgqeni wakho wokukhiqiza.

Ukucushwa okujwayelekile

- • Umhlahlandlela Wewebhu we-BST

- • Ikhanda lokuskena lomthombo owodwa

- • Ukususwa Kwemfucuza

- • Hlehlisa umoya

Ukucushwa ongakukhetha

- • Ikhanda Lokuskena Kwemithombo Ekabili

- • Ukufundwa Kwekhodi Yebha

| Imodeli No. | I-LC350 |

| Amandla e-laser | 150W, 300W, 600W |

| Ubukhulu bokusika ububanzi | 340mm |

| Ubukhulu bewebhu ububanzi | 350mm |

| Ubukhulu bedayamitha yewebhu | 750 mm |

| Isivinini sewebhu | ≥80m/min |

Imodeli ehlangeneI-LC230 Laser Die Cutterngezinketho ze-lamination, i-UV varnishing kanye ne-slitting.Uzakwethu othembekile ongakusiza ukuthi uqale ibhizinisi elisha.

| Imodeli No. | I-LC230 |

| Amandla e-laser | 100W, 150W, 300W |

| Ubukhulu bokusika ububanzi | 220mm |

| Ubukhulu bewebhu ububanzi | 230mm |

| Ubukhulu bedayamitha yewebhu | 400mm |

| Isivinini sewebhu | ≥40m/min |