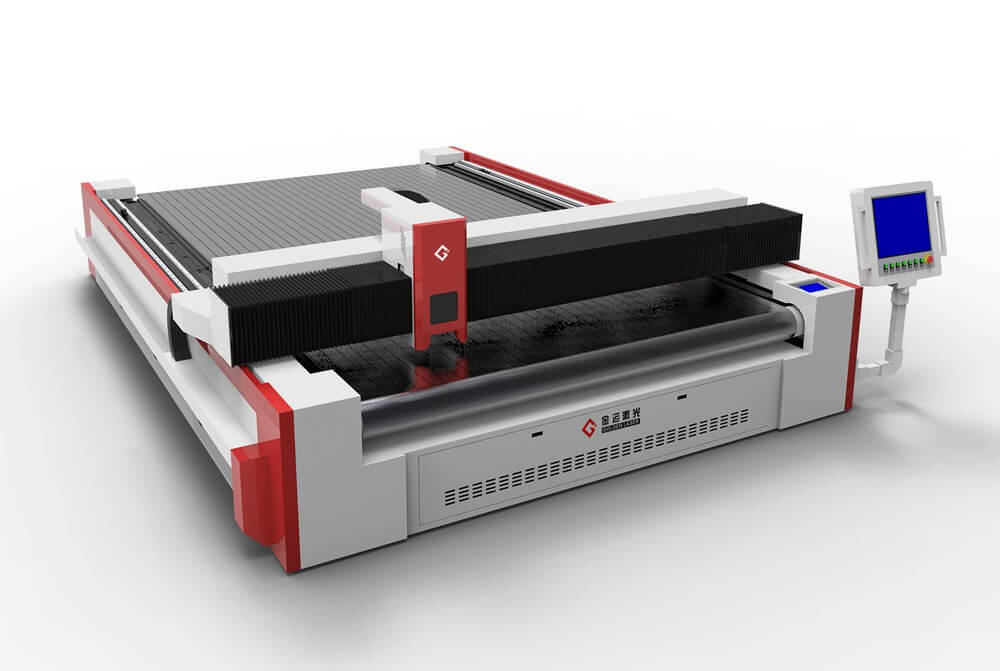

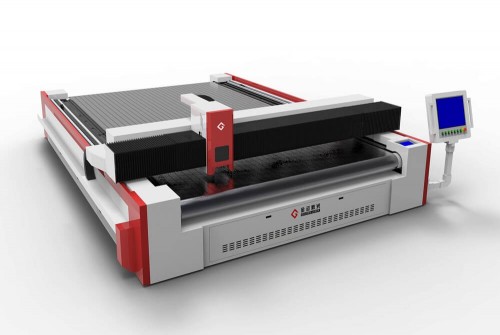

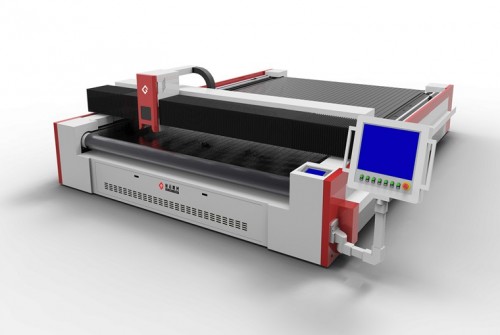

JMC Series CO2 Laser Cutter in Details

Gear & Rack driven

High precision grade Gear & Rack driving. Cutting efficiency with speed up to 1200mm/s and acceleration of 10000mm/s2, and can maintain long-term stability.

World class CO2 laser source (Rofin)

High reliability, low maintenance efforts and excellent beam quality.

Vacuum honeycomb conveyor working table

Flat, fully automatic, low reflectivity from laser.

Control system

With Independent intellectual property rights, tailored to cutting textiles.

Yaskawa Servo Motor

High precision, stable speed, strong overload capability and low noise temperature rise.

Auto-feeder: tension correction

Linked with the laser cutter to achieve continuous feeding and cutting.

Technical Specifications of the Cutting Laser Machine

| Laser type | CO2 laser |

| Laser power | 150W / 300W / 600W / 800W CO2 RF tube |

| 150W / 300W CO2 glass tube | |

| Cutting area (W×L) | 1600mm×3000mm (63” ×118”) |

| Cutting table | Vacuum conveyor working table |

| Cutting speed | 0-1200mm/s |

| Acceleration speed | 12000mm/s2 |

| Repeat positioning accuracy | ±0.03mm |

| Positioning accuracy | ±0.05mm |

| Motion system | Servo motor, gear & rack driven |

| Graphics format supported | AI, BMP, PLT, DXF, DST |

| Power supply | AC220V±5% / 50Hz |

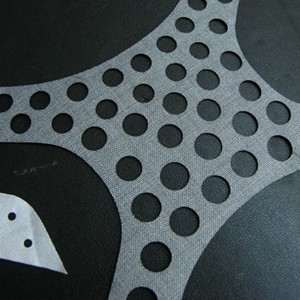

The advantages of laser cutting for textile over traditional cutting tools:

The application industry and materials of laser cutting for textile:

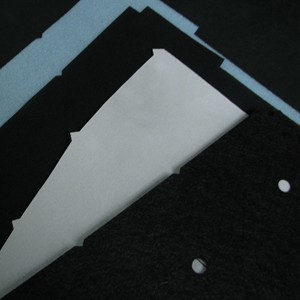

Materials

polyester (PES), viscose, cotton, nylon, nonwoven and woven fabrics, synthetic fibers, polypropylene (PP), knitted fabrics, felts, polyamide (PA), glass fiber (or glass fibre, fiberglass, fibreglass), Kevlar, aramid, polyester PET, PTFE, paper, foam, cotton, plastic, etc.

Applications

1. Clothing Textiles: technical textiles for clothing applications.

2. Home Textiles: carpets, mattress, sofas, curtains, cushion materials, pillows, floor and wall coverings, textile wallpaper, etc.

3. Industrial Textiles: filtration, air dispersion ducts, etc.

4. Textiles used in automotive and aerospace: aircraft carpets, cat mats, seat covers, seat belts, airbags, etc.

5. Outdoors and Sports textiles: sports equipment, flying and sailing sports, canvas covers, marquee tents, parachutes, paragliding, kitesurf, boats (inflatable), air balloons, etc.

6. Protective textiles: insulation materials, bulletproof vests, etc.