Heavy steel pipe profile cutting - P30120 Pipe Laser Cutter

Technical Specifications of the Pipe Laser Cutting Machine

| Model |

P30120 |

| Tube length |

12000mm |

| Tube diameter |

20mm~300mm |

| Laser source |

IPG / nLight fiber laser resonator |

| Laser power |

700W / 1000W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

| Laser head |

Raytools, Precitec ProCutter |

| Maximum rotate speed |

120r/min |

| Repeat positioning accuracy |

±0.03mm |

| Maximum positioning speed |

90m/min |

| Acceleration |

1.5g |

| Cutting speed |

Depend on materials, laser source power |

| Electric power supply |

AC380V 50/60Hz |

Features of the Pipe Laser Cutting Machine

Chunk

Fast speed up to 120 rpm

4.4KW high power servo motor. The gear is driven directly, the power transmission rate is higher, and the transmission speed is faster.

High durability

Gear and clamp are quenched to ensure accuracy, durability and no deformation. The roller that directly contacts the pipe is made of high-hardness bearing steel, durable and wear-resistant.

Easy to adjust

The clamp adopts the mode of two-gear adjustment. Pipe diameter 20-100mm, 100-200mm, no need to adjust; pipe diameter 20-200mm, no need to replace the clamp.

High sealing

The chuck design adopts high sealing to prevent cutting debris and dust from entering the interior, affecting or shortening the service life of the inner cylinder and valve.

Advanced chuck clamping system

Corner fast cutting system

Corner fast response, improves cutting efficiency greatly.

Multi-axis linkage

Multi-axis (feeding axis, chuck rotation axis and the laser cutting head) linkage when the laser cutting head is moving.

Automatic floating support

The floating support is controlled by the servo motor and it can adjust the support point according to the pipe diameter quickly.

Welding seam recognition

Identify welding seam to avoid welding seam during cutting process automatically, and prevent holes from popping.

Automatic correction

For the bent and deformed pipe, the automatic correction function can realize the segmented edge search, automatic correction find the center point of the curved tube to cut, and ensure the cutting precision.

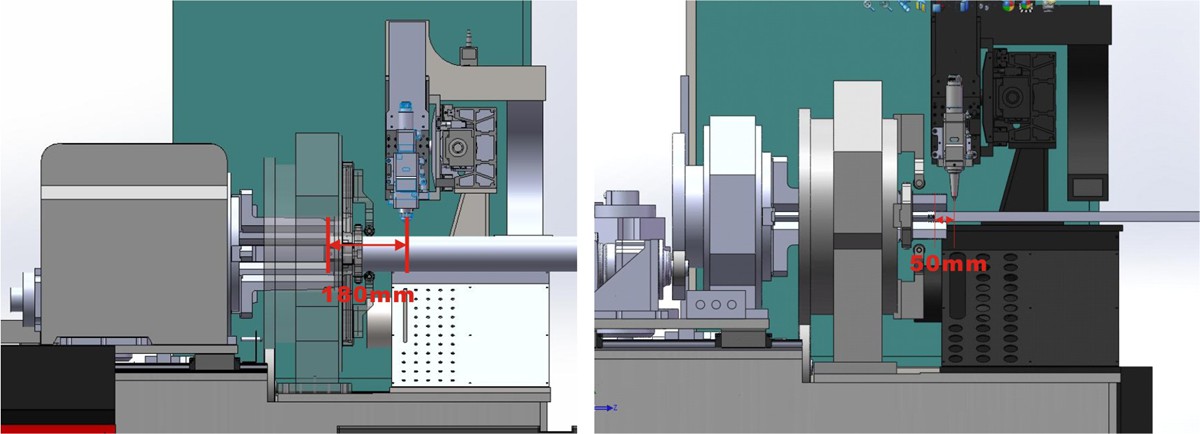

“Zero” Wastage

When cutting to the last part of the tube, the front chuck jaws are automatically opened, and the rear chuck jaws pass through the front chuck to reduce the cutting blind area.

Optional – the third axis cleaning inner wall device

During the laser cutting process, the slag will inevitably adhere to a part of the inner wall of the opposite pipe. In particular, some pipes with smaller diameters will have more slag. For high demand applications, the third axis cleaning inner wall device can be added to prevent slag adhering to the inner wall.

German PA control software

Spanish Lantek software - Focus on tube parts design module

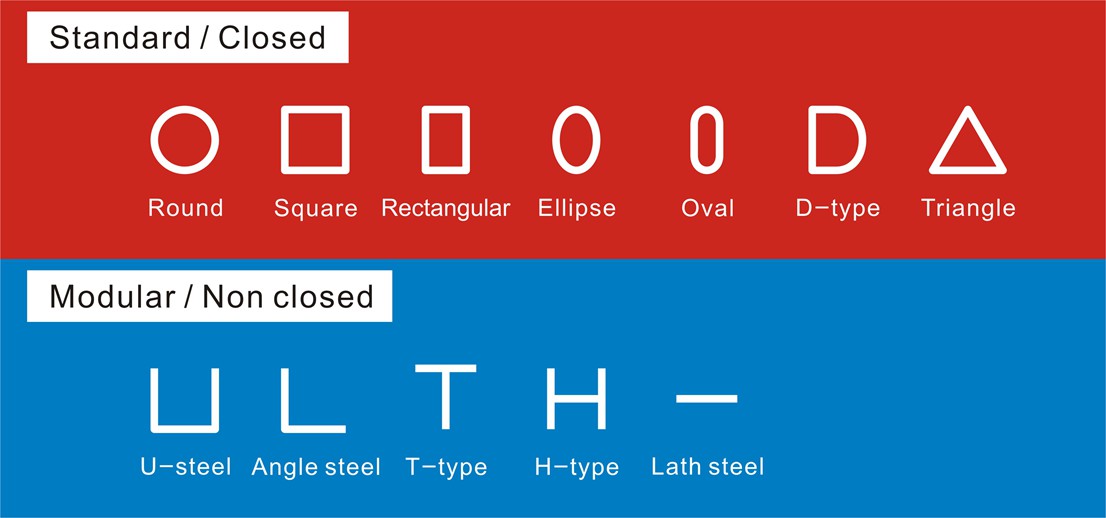

Lantek Flex3d supports a variety of pipe types

Applications of the Pipe Cutting Laser Machine

Applicable material

Stainless steel, mild steel, carbon steel, aluminum, brass, copper, galvanized steel, alloy steel, etc.

Applicable Industry

Furniture, medical device, fitness equipment, display rack, automobile industry, agriculture and forestry machinery, fire pipelines, steel frame structures, oil exploration, bridges, ships, structure components, etc.

Applicable tube type: round tube, square tube, rectangular tube, oval tube, ellipse tube, waist tube, triangle pipe, D-type, channel steel, angle steel, U-bar, T-type, H-type, I-beam, lath steel, etc.