Modern transportation is a combination of strength and beauty. The metal alloy endows vehicles with powerful kinetic energy and protective function; the non-metal portion comforts the passengers and brings the enjoyment of beauty. Laser cutting and engraving technology helps achieving “Strength and Beauty”.

The automotive industry is one of the world's largest economic sectors by revenue, there is such a wide range of companies and organizations involved in the design, development, manufacturing, marketing, and selling related products. And specified to a car, there is very accurate segmentation such as interior upholstery, car seat, airbags, heating system and etc… While laser technology has been widely used in the automotive industry.

Application Sectors

Laser processing application sectors in the automotive industry with CO₂ laser systems from Goldenlaser

Cutting airbags with laser cutting machines allows very efficient R&D and production stage. Any changes in design could be implemented on laser cutting machines within minutes. At the end laser cut bags are consistent in size, shape and patterns. Laser cutting of airbag cloth has the advantage that besides the fast cuts the cloth is melted at the cutting edges immediately, which avoids fraying. Layout of the patterns are usually done highly efficient as well.

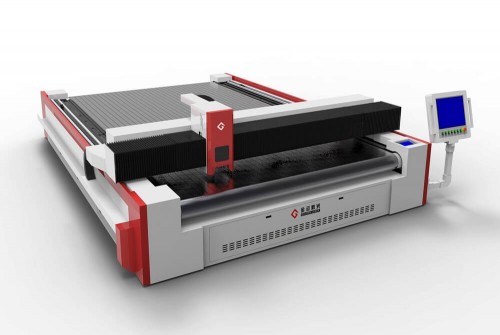

Model No.: JMCCJG-250350LD

Laser cutting upholstery is very well known process. Laser cut part are precise, consistent and very accurate compare to other cutting processes. Laser cutting textile, leather, leatherettes, felt, suede and even complex functional materials is allowing to bring highly efficient process to automotive industry. Laser cutting can realize high automatically continuous cutting for an entire roll of material with precise and clean cutting results.

Thermal technology for car seats is a quite common application now. Each technology innovation not only upgrades the products itself, but also pays close attention to the users. The optimal goal of thermal technology is to create the highest level of comfort for passengers and elevate the driving experiences. The traditional process to manufacture heated car seats is to die cut the cushions first and then stitch the conductive wire on the cushion. Such method results low cutting quality, leaves material scraps everywhere and is time-consuming. While laser cutting machine, on the other hand, simplifies the whole manufacturing steps, improves the production efficiency, and saves production materials and time for manufacturers. It highly benefits the customers with high quality heated car seats.

Key importance of laser cutting for thermoelectrically heat car seat

Golden Laser offers Laser Cutting Machines to produce a wide array of parts and components from all types of insulation products including:

• Flame retardant electrical insulation products

• Thermal insulation products (high-temperature resistant textiles, heat protection textiles, thermal insulating sleevings)

• Sound insulation products

Key importance of laser cutting for insulation products

The dust extraction of sanding process is always one of the most important part of the automotive market, the most common disc 5’’ or 6’’ ensures superior dust and debris extraction. The traditional cutting method is rotary die cutting. The cutting tools cost thousands of dollars and these dies wear out pretty quickly that making the production costs extremely high. How to realize lower cost production is a challenge! Our high speed multi-heads GALVO laser machine changes the die cutting history.