Traditional Process

In traditional fabric printing application, it usually adopts chemical processing. The processing way is quite complicated, should make module, and need several steps and work with other equipment together. Also should strictly follow the restrictions of environmental production.

Complex processing with sameness products makes low added value, GOLDENLASER dedicated in this field for many years and finally R&D an environment friendly laser creatively engrave machine.

Why Laser?

This solution combines laser technology with digital graphic design. Using laser heat to vaporize fabric surface and achieve a variety of personalized printing effects. It does not need to make module, no need dye or wash neither. One worker could control several machines, no need other equipment assistance. The digital graphics is easy to make, the pattern is flexible, and the laser engraved image is clear and stereoscopic. The complete process does not require any chemical composition and is environmentally friendly.

In suede, denim, home textile, clothing and current popular small batch, personalized fast fashion applications, Golden Laser creative engraving solution greatly enriches the craftsmanship and enhances the artistic effect.

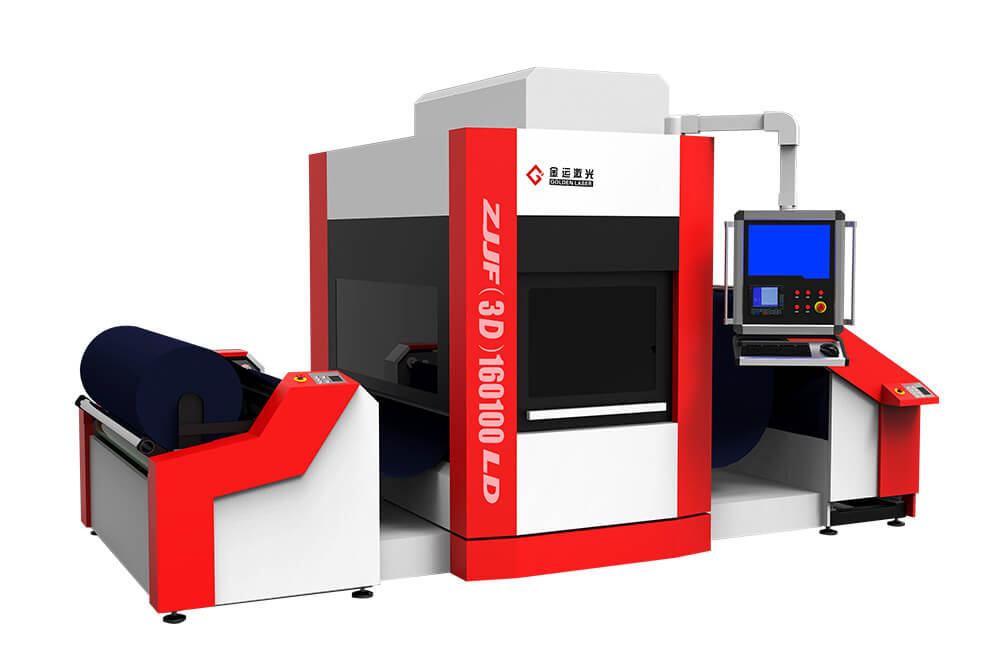

3D dynamic large-format engraving and perforating technology:

Using flying engraving technology, one time engraving area can reach 1800mm without any splicing, supporting 1600mm width to unlimited length of roll fabrics engraving, loading and unloading at the same time. It is continuous automatic processing of the entire roll of fabric without the need for pauses or manual assistance.

Machine Features

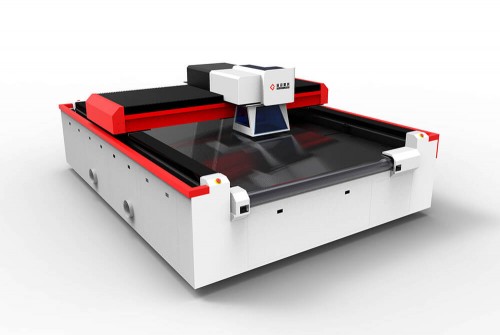

• Golden Laser’s roll-to-roll laser engraving system brings significant added value to fabrics by means of digital creative laser engraving.

• It can do the various engraving, marking and hollowing design immediately, no need for a printing roller in advance.

• The 3D dynamic focus technology can achieve the fly engraving within 1800mm at one time.

• The feeding, rewinding and the laser engraving are carried out at the same time to ensure the continuity of the engraving graphics, and the length of the engraving can be extended indefinitely.

Main Configuration

• Standard equipped with 500W CO2 RF metal laser generator.

• Red light positioning with automatic feeding correcting system, ensure high speed processing with high precision.

• 5" LCD screen digital control, supporting a variety of connection ways, both offline and online operation are available.

Technical specifications of the roll to roll Galvo engraving laser machine

| Laser type | CO2 RF metal laser tube |

| Laser power | 300W / 600W / 800W |

| Working area | 1600mm×1000mm |

| Working table | Conveyor working table |

| Motion system | Offline Servo control system |

| Cooling system | constant temperature water chiller |

| Power supply | AC380V±5%, 50HZ or 60HZ |

| Format support | AI, BMP, PLT, DXF, DST, etc. |

| Standard configuration | Roll to roll feeding and rewinding system, Auxiliary ladder, built-in control panel, blowing system |

Application

Processes: Marking, engraving and cutting of textiles on rolls.

Suitable but not limited to natural and synthetic textiles, technical textiles, leather, suede, denim, EVA, microfibers.

Applicable but not limited to fast fashion, personalized customization, textile and apparel, home textiles, interior designs, carpets & mats.