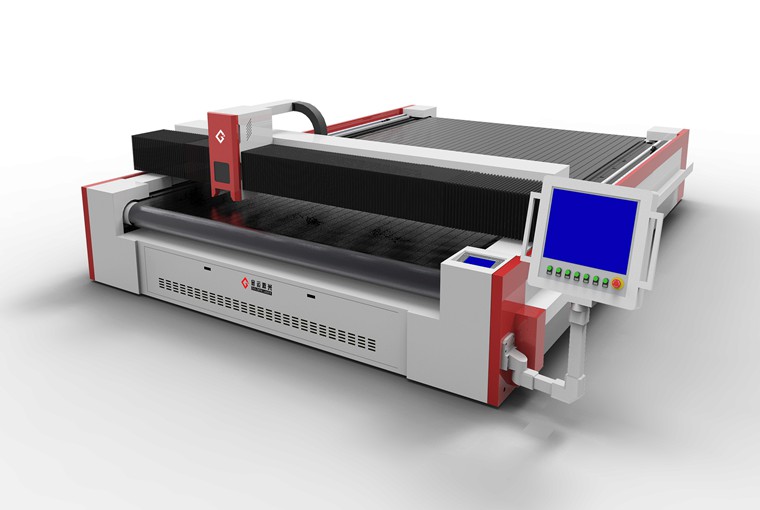

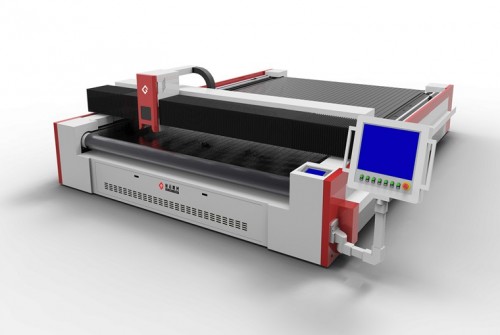

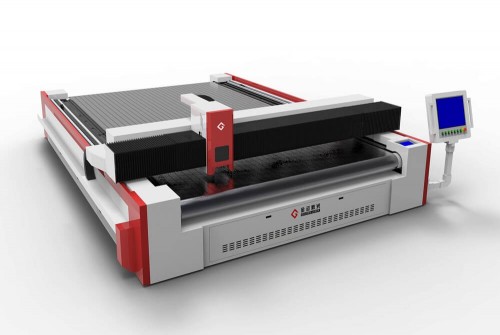

Wide Format Laser Cutting Machine

Developed specifically for the carpet industry, the laser cutting machine can cut any pattern and size of various carpet, rug and car mat materials to meet the differentiated needs of customers and improve the added value of products.

Thanks to the conveyor and the automatic feeding system, the laser cutter can quickly and continuously cut a variety of wide and thick fabrics, such as carpets, automotive interiors, home textile, industrial fabrics, etc.

What are the advantages of laser cutting of carpets?

JMC Series CO2 Laser Cutter Machine in Details

Gear & Rack drive

High precision grade Gear & rack driving. Cutting efficiency with speed up to 1200mm/s and acceleration 10000mm/s2, maintaining long-term stability.

World class CO2 laser source (Rofin)

High reliability, low maintenance efforts and excellent beam quality.

Vacuum conveyor working table

Flat, fully automatic, low reflectivity from laser.

Control system

With Independent intellectual property rights, tailored to cutting carpet mat.

Yaskawa Servo Motor

High precision, stable speed, strong overload capability and low noise temperature rise.

Auto-feeder: tension correction

Linked with the laser cutter to achieve continuous feeding and cutting.

Technical Specifications of the Cutting Laser Machine

| Laser type | CO2 laser |

| Laser power | 150W / 300W / 600W / 800W CO2 RF tube |

| 150W / 300W CO2 glass tube | |

| Cutting area (W×L) | 2600mm×4000mm (102.3”×157.4”) |

| Cutting table | Vacuum conveyor working table |

| Cutting speed | 0-1200mm/s |

| Acceleration (Max.) | 12000mm/s2 |

| Repeat positioning accuracy | ±0.03mm |

| Positioning accuracy | ±0.05mm |

| Motion system | Servo motor, gear and rack driven |

| Format supported | AI, BMP, PLT, DXF, DST |

| Power supply | AC220V±5% 50Hz |

| Lubrication system | Automatic lubrication system |

| Options | Auto feeder, red light positioning, marker pen, 3D Galvo, double heads |