Small batch and multi-variety processing in the garment industry with laser cutting

Clothing industry demand:

single layer cutting / less consumables / high cutting precision / graphic digitalization for easy management

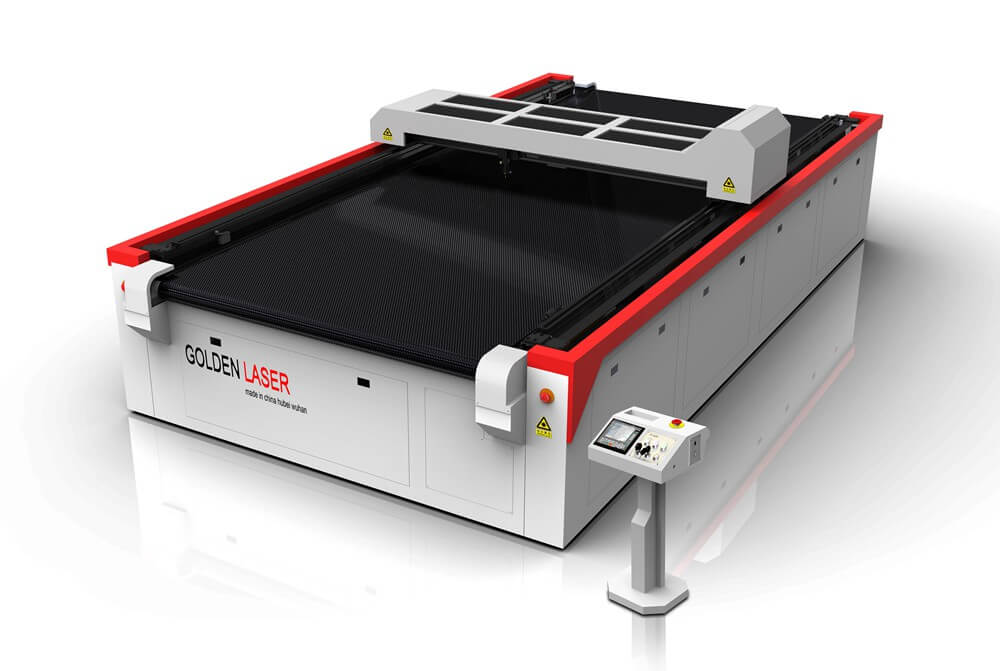

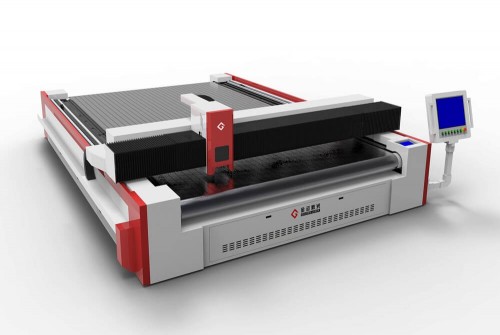

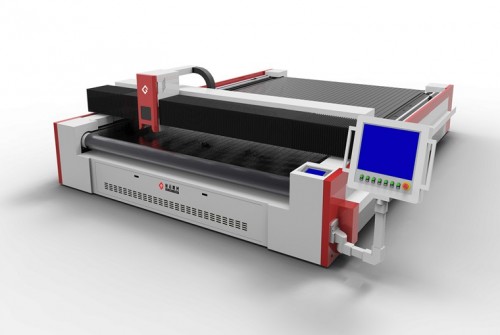

Laser Cutting Machine Features

Advantages of Laser Cutting

In the current cutting methods, the manual cutting is the most widely used, followed by the mechanical cutting. Both of these processing methods are applied to large volume cutting work, and the cut pieces are not accurate..

Laser cutting machine is suitable for small batches and multi-variety garment cutting, especially for fast fashion and various customization needs.

Traditional cutting has a high demand for tailors and has raw edges after cutting. The laser cutting has a high consistency and automatic edge sealing.

Making holes, strips, hollowing patterns, engraving designs, obtuse angles, ultra-long format cutting. The laser perfectly handles any details.

Software Package

For customers who have no designers and have not used CAD design software, we provide automatic photo digitizer, which does not require users to store cardboard and acrylic sheets in large quantities. Laser cutting machine converts the pattern into digital graphics and stores it on the computer. And can automatically copy design, and automatically extract the outline of the graphic.

In addition, for small and medium-sized clothing manufacturers or customers with design studios, we provide the laser cutting machine with CAD design, automatic grading, marker making software package to achieve automated processing.

Technical Specifications of the Cutting Laser Machine

| Laser source | DC glass laser tube / RF metal laser tube |

| Laser power | 80 watt ~ 150 watt |

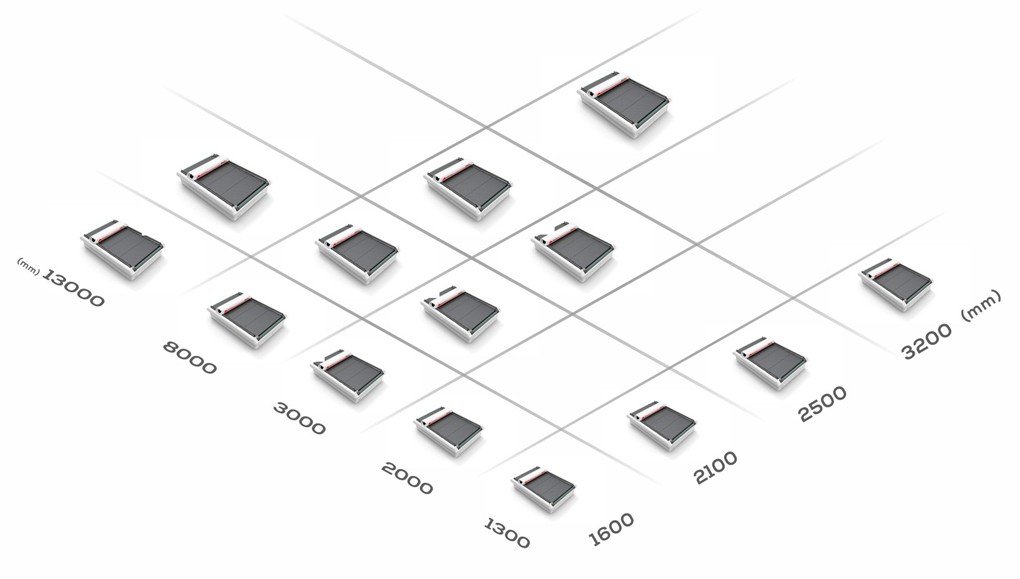

| Working area (W×L) | 1600mm×3000mm (63” × 118”) |

| Working table | Vacuum conveyor working table |

| Software | GOLDENLASER cutting software (standard), camera recognition system (optional), CAD design software (optional), marker software(optional), photo digitizer system(optional) |

| Fully automatic | Auto feeding system |

| Other options | Red light positioning, mark pen |