Benefits of the laser engraving cutting machine

High Speed

High speed double gear rack driving system

Galvo & Gantry Integration

Fast Galvo engraving and large format X-Y axis cutting

High Precision

Precise laser beam size up to 0.2mm

Multi-function

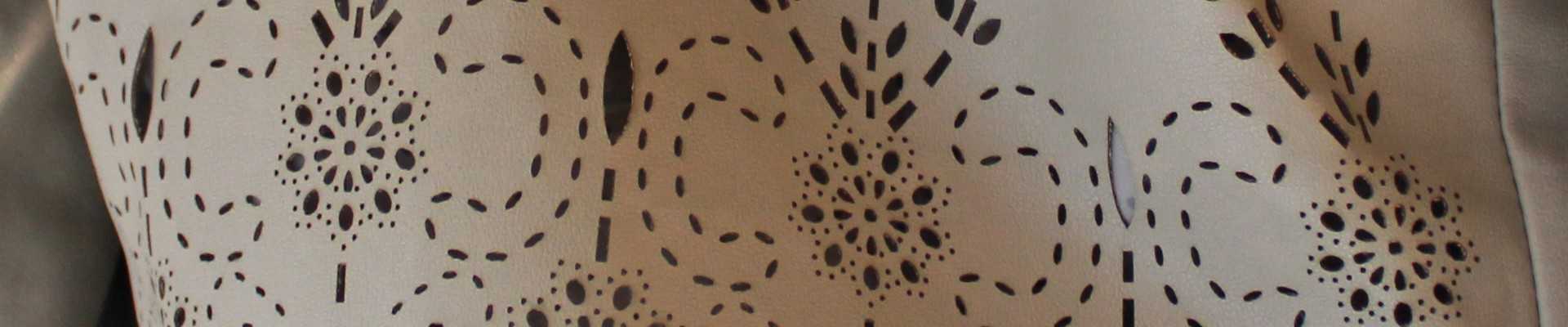

Engraving, perforating, hollowing, cutting of various leather and textile

Flexible

Processing any design. Save tool cost, save labor cost and save materials

Automated

Automatic laser processing roll to roll thanks to conveyor system and auto feeder

Machine features of the laser engraving cutting system

Technical specifications

of the Galvo & gantry laser engraving cutting machine

| Model |

ZJ(3D)-170200LD |

ZJ(3D)-160100LD |

| Working area (W×L) |

1.7m×2m (66.9"×78.7") |

1.6m×1m (63”×39.3”) |

| Laser type |

CO2 RF metal laser tube |

|

| Laser power |

150W / 300W / 600W |

|

| Galvo laser |

3D dynamic focus, Galvanometer scanner, scanning area 450mm×450mm |

|

| Working table |

Zn-Fe alloy honeycomb vacuum conveyor |

|

| Mechanical system |

Servo motor, Gear & Rack driven |

|

| Power supply |

AC220V±5% 50 / 60Hz |

|

| Format support |

PLT, DXF, AI, BMP, DST, etc. |

|

| Options |

Auto feeder, CCD camera |

|

Application of the CO2 laser cutting engraving machine

Process materials: leather, synthetic leather, rexine, PU, textile, EVA foam and other non-metal materials.