Features of the laser cutter machine

Material saving

The nesting software is easy to operate, for automatic nesting, eliminating the need for professional nesting personnel, saving 7% or even more materials.

Simplify the process

One machine for multi-purpose. Capable of handling cutting from roll to pieces, number marking on cut pieces and punch holes.

High precision

Spot size is up to 0.1mm, perfectly cutting angle, holes and a variety of complex designs and shapes.

Non-contact process

Clean and perfect cutting edges. Less efforts of clearance due to reduced dust production when cutting

Automation

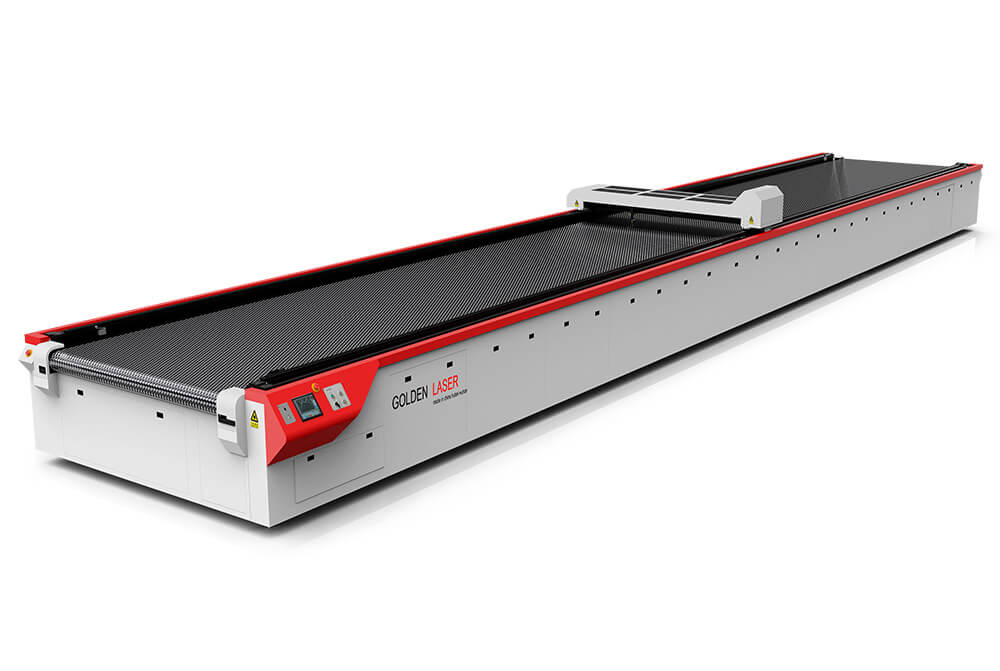

Auto-feeder for automatic feeding. Thanks to the collecting working table, it solves the difficulties for collecting materials due to the large number of cut pieces.

Practicability

Perfectly cutting of polyester, polypropylene, non-woven, paper, nylon, foam, cotton, PTFE and other textile materials.

Comparison of laser cutting with knife cutting and punching

|

Laser cutting |

Knife cutting |

Punching |

|

| Cutting edges |

Smooth |

Wear |

Wear |

| Seamless cutting |

Yes |

No |

No |

| Marking / Engraving |

Yes |

No |

No |

| Tool wear |

No |

Easy to wear |

High cost for replacing tool |

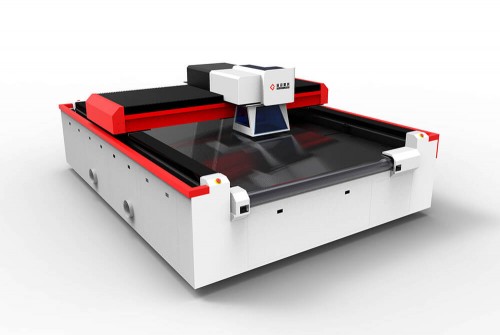

Technical specifications of the laser cutting machine

| Working area (W×L) | 1600mm×6000mm (63” ×236”), 1600mm×9000mm (63” ×354”), 1600mm×13000mm (63” ×511.8”), 2100mm×11000mm (82.6” ×433”), 2500mm×11000mm (98.4” ×433”), … |

| Working table | Vacuum conveyor working table |

| Laser source | Co2 RF metal laser tube |

| Laser power | 150 watt / 300 watt / 600 watt |

| Mechanical system | Servo driven; Gear & rack driven |

| Format supported | AI, BMP, PLT, DXF, DST |

| Power supply | AC220V±5% / 50Hz |

Options

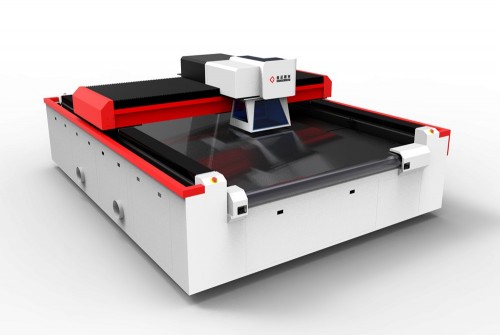

Application of the cutting laser machine

Aviation: aircraft carpets, etc.

Outdoors and sporting goods: parachute, paraglider, sail, tent, canopy, awning, marquee, etc.

Technical textiles and industrial fabrics