Izingxenye Eziyinhloko Zomshini Wokusika Ishubhu Laser

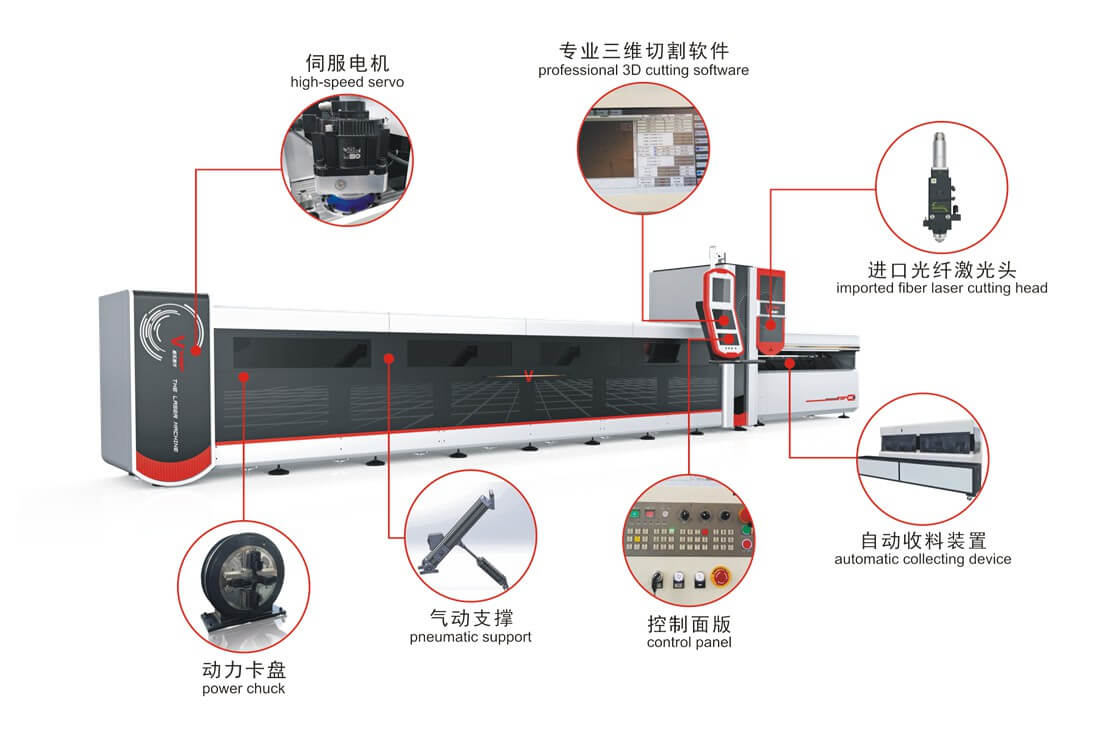

Isistimu ye-chuck clamping ethuthukisiwe

• I-Chuck center yokuzilungisa, ilungisa ngokuzenzakalelayo amandla okubamba ngokuvumelana nemininingwane yephrofayili yeshubhu futhi iqinisekisa ukuthi akukho monakalo epayipini elincanyana.

• Ama-chuck ashukumisayo ahambisana nezinhlobonhlobo zamapayipi ngaphandle kokulungisa imihlathi.

• I-strike clamp ende.Asikho isidingo sokulungisa i-clamp lapho ububanzi bepayipi bushintsha phakathi kuka-100mm

Corner fast cutting system

Ukusabela okusheshayo kwekhona, kuthuthukisa ukusebenza kahle kokusika kakhulu.

Ukuxhumana kwama-axis amaningi

I-Multi-axis (i-axis yokudla, i-axis yokuzungezisa i-chuck kanye nekhanda lokusika i-laser) ukuxhumana lapho ikhanda lokusika le-laser lihamba.

Idivayisi yokuqoqa ezenzakalelayo

• Umshini wokusekela ontantayo uqoqa amapayipi aphelile ngokuzenzakalelayo.

• Ukwesekwa okuntantayo kulawulwa injini ye-servo futhi ingakwazi ukulungisa iphuzu lokusekela ngokuvumelana nobubanzi bepayipi ngokushesha.

• Iphaneli yokusekela elintantayo ingabamba ipayipi elikhulu lobubanzi liqinile.

Ukusekela Okuzenzakalelayo Okuntantayo

Ngokusho koshintsho lwesimo sepayipi, ukuphakama kokusekela kungalungiswa ngokuzenzakalelayo ngesikhathi sangempela ukuze kuqinisekiswe ukuthi phansi kwepayipi kuhlale kungenakuhlukaniswa kusukela phezulu kwe-shaft yokusekela, edlala indima yokusekela ipayipi ngamandla.

Ukuqashelwa komthungo wokushisela

Isikhundla se-welding seam yepayipi singabonakala ukuze kuqinisekiswe ukuthi indawo yokusika igwema i-welding seam ngesikhathi sokucubungula futhi igweme inkinga yemigodi yokuqhuma emgqeni we-welding.

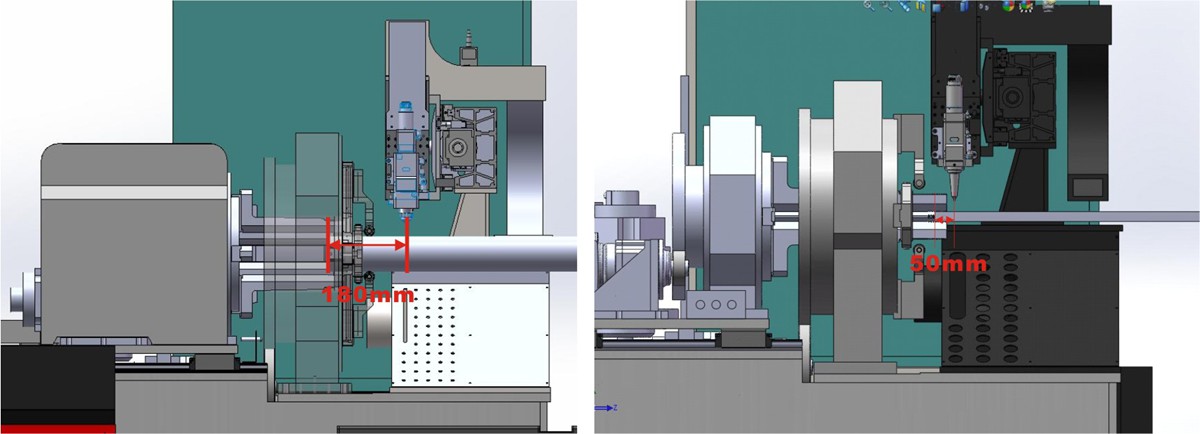

"Zero" Ukumoshwa

Lapho usikwa kuze kube sengxenyeni yokugcina yeshubhu, imihlathi ye-chuck yangaphambili ivuleka ngokuzenzakalelayo, futhi imihlathi ye-chuck yangemuva idlula i-chuck yangaphambili ukunciphisa indawo eyimpumputhe yokusika.

• Ububanzi beshubhu bungaphansi kuka-100 mm, izinto ezimoshekayo 50-80 mm

• Ububanzi beshubhu bungaphezu kuka-100 mm, izinto ezimoshekayo 180-200 mm

Ongakukhetha - i-eksisi yesithathu yokuhlanza idivayisi yangaphakathi yodonga

Phakathi nenqubo yokusika i-laser, i-slag izonamathela nakanjani engxenyeni yodonga lwangaphakathi lwepayipi eliphambene.Ikakhulukazi, amanye amapayipi anama-diameter amancane azoba ne-slag eyengeziwe.Ngezinhlelo zokusebenza ezifunwa kakhulu, i-axis yesithathu yokuhlanza idivayisi yangaphakathi yodonga ingangezwa ukuvimbela i-slag ukunamathela odongeni lwangaphakathi.

I-German PA control software

- • Ikhasi elilodwa liqeda yonke imisebenzi esebenziseka kalula!

- • Yenza ngokwezifiso isixhumi esibonakalayo ngokushesha, esikahle kakhulu!

- • Engeza isixhumi esibonakalayo esizimele ukuze uxazulule ngokushesha izinkinga ezikusayithi, uhlakaniphe kakhulu!

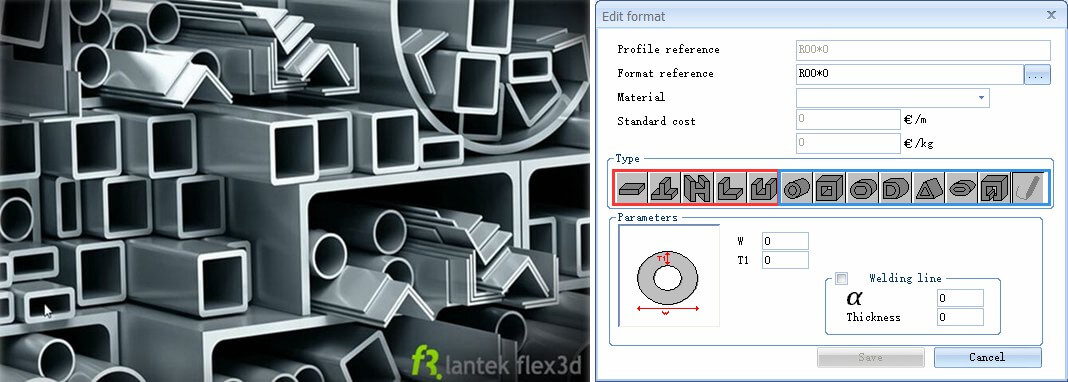

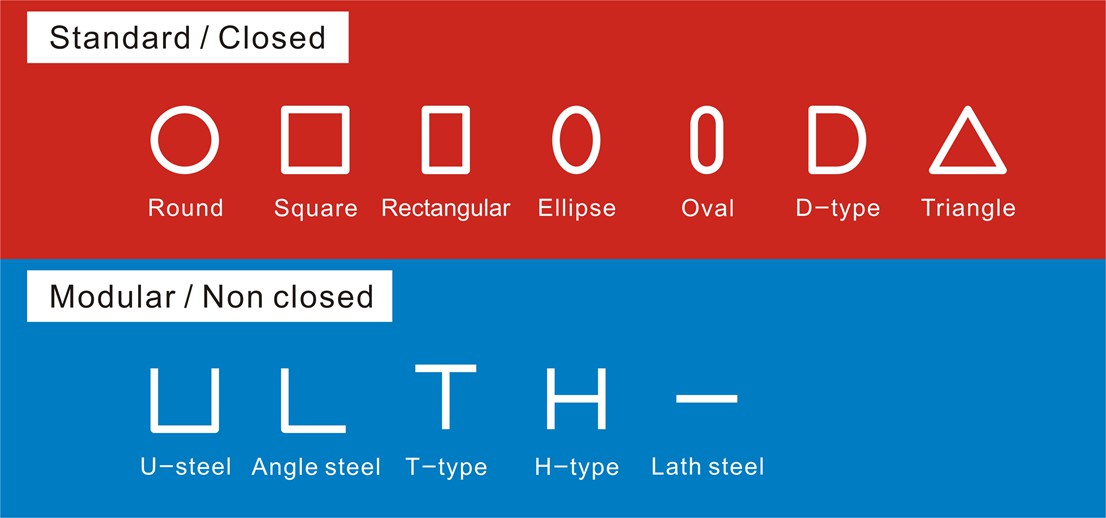

I-Lantek Flex3d isekela izinhlobo zamapayipi ezihlukahlukene

- • Uhlobo lweshubhu olujwayelekile: Ishubhu eliyisiyingi, ishubhu yesikwele, ishubhu yohlobo lwe-OB, ishubhu yohlobo lwe-D, ishubhu elingunxantathu, ishubhu eliqanda, njll. Kanye nepayipi elimise okukhethekile lobubanzi obulinganayo.

- • Ngesikhathi esifanayo, i-flex3d inamamojula asebenzayo wokusika iphrofayili, engasika insimbi ye-engeli, insimbi yesiteshi kanye nensimbi emise okwe-H, njll.

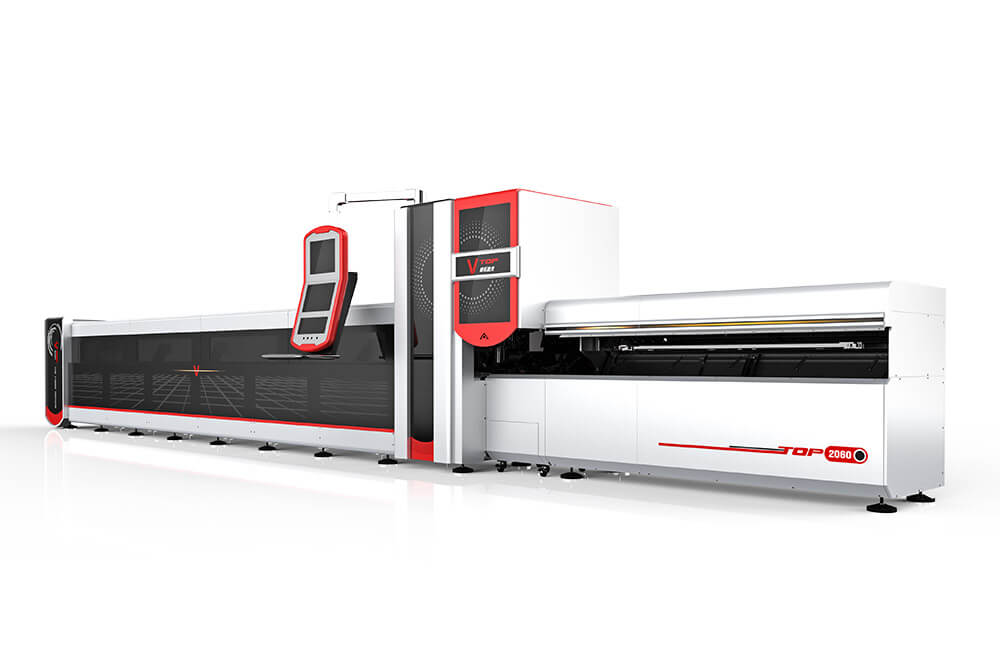

Imininingwane Yobuchwepheshe Yomshini Wokusika Ishubhu Laser

| Imodeli | P2060/P3080/P30120 |

| Ubude beshubhu | 6000mm / 8000mm / 12000mm |

| Ububanzi beshubhu | 20mm ~ 200mm / 20mm ~ 300mm |

| Umthombo we-Laser | IPG / nLight fibre laser resonator |

| Amandla e-laser | 700W / 1000W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

| Ikhanda le-laser | I-Raytools, i-Precitec ProCutter |

| Isivinini esikhulu sokuzungezisa | 120r/min |

| Phinda ukunemba kokuma | ±0.03mm |

| Isivinini sokuma esiphezulu | 90m/min |

| Ukusheshisa | 1.5g |

| Ukusika isivinini | Kuncike ezintweni, amandla omthombo we-laser |

| Ukunikezwa kwamandla kagesi | I-AC380V 50/60Hz |

Ukusetshenziswa komshini we-Laser Cutting Tube

Izinto ezisebenzayo

Ikakhulukazi ukusika amashubhu ensimbi afana neshubhu eliyindilinga, ishubhu lesikwele, ishubhu elingunxande, ishubhu eliqanda, ishubhu okhalo, ipayipi elingunxantathu, insimbi yesiteshi, insimbi ye-angle, i-U-bar, uhlobo lwe-T, i-I-beam, i-lath steel, njll.

Imboni Esebenzayo

Ifenisha, idivayisi yezokwelapha, okokusebenza kokufaneleka, indawo yokubonisa, imboni yezimoto, imishini yezolimo nezamahlathi, amapayipi omlilo, izakhiwo zohlaka lwensimbi, ukuhlola uwoyela, amabhuloho, imikhumbi, izingxenye zesakhiwo, njll.